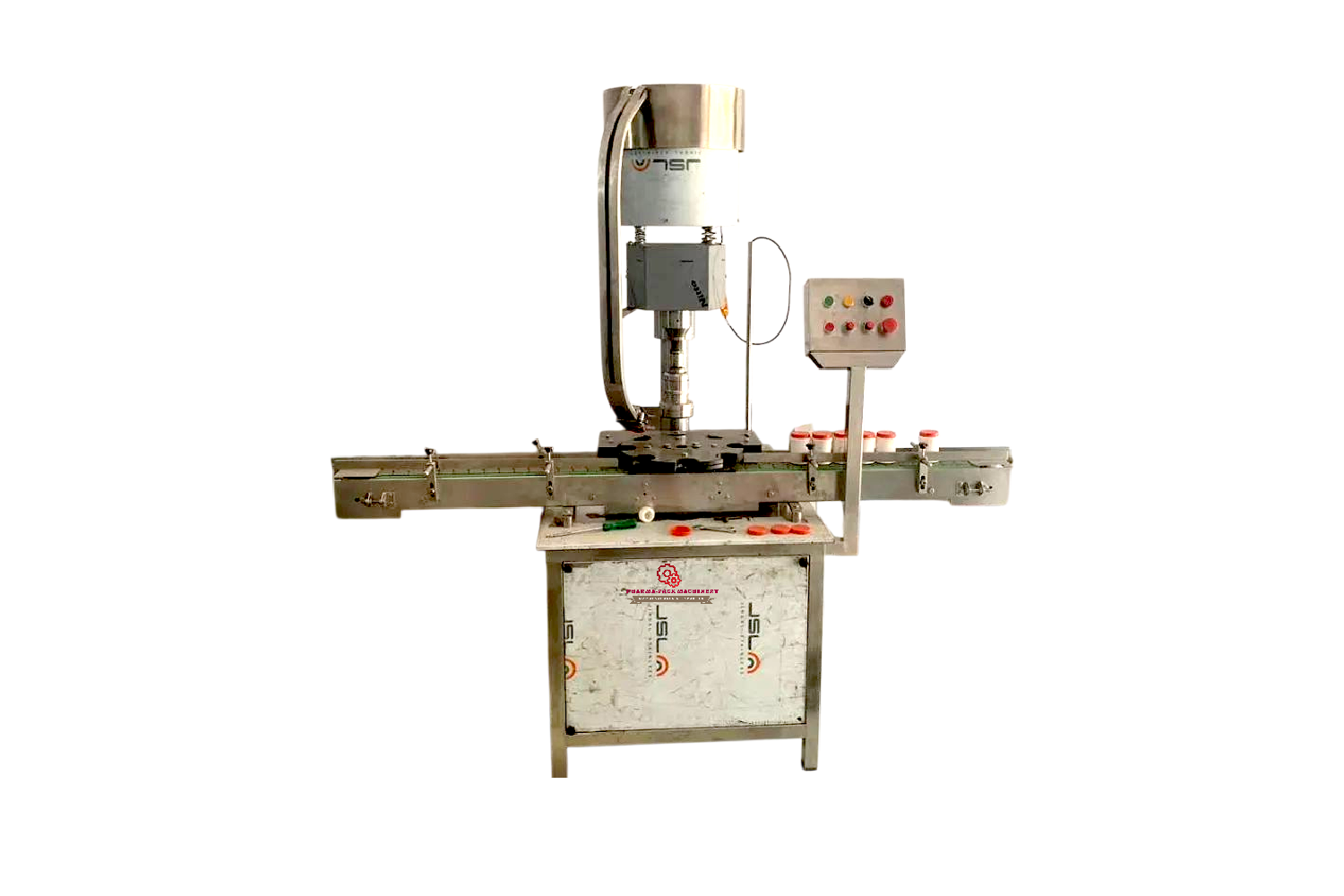

Automatic 1 Head Screw/ROPP Cap Sealing Machine

| Parameter | Typical / Example Value | Notes / Optional Variants |

|---|---|---|

| Number of Sealing Heads | 1 | Single head; higher throughput with 4, 6, 8 head variants. |

| Cap Type | Screw cap or ROPP (Roll On Pilfer Proof) | Adaptable for different cap styles via change parts. |

| Cap Size Range | Ø 19-38 mm (Height ~15-18 mm) | Larger/smaller caps possible with change parts. |

| Bottle / Container Diameter | Ø 20-60 mm (round) | Square/flat bottles accommodated with star wheel / guide adjustments. |

| Bottle / Container Height | 50-350 mm | Adjustable conveyor & star wheel height. |

| Output / Speed | 2000-2400 bottles/hour (~30-40 bottles/min) | Speed depends on bottle/cap size; higher with multi-head machines. |

| Power / Electrical Supply | Main motor ~1 HP (0.75-1 kW), 415V, 3-phase, 50 Hz | Cap feeder vibrator motor: 0.3-0.5 kW; other voltages possible. |

| Feeding Mechanism for Caps | Vibratory bowl feeder or cap feeding bowl with chute | |

| Cap Pick-Up Method | Chute pick-up from feeder; star wheel or infeed star plate | Ensures bottle alignment under sealing head. |

| Conveyor / Transfer | SS slat chain conveyor; star wheel positioning; adjustable guide rails | |

| Height of Conveyor | 800-850 mm (±50 mm) | Matches with other inline machines. |

| Machine Dimensions (L X W X H) | ≈1.8-2.0 m X 0.8-1.0 m X 1.7-2.0 m | Single head machine; varies by manufacturer. |

| Weight (Approx.) | 300-400 kg | Depends on build materials. |

| Material of Construction | External: SS 304 / SS 316; Contact parts: SS 316 | Frame may be mild steel with SS cladding. |

| Adjustability & Change Parts | Change parts: star wheel, back guide, cap die, chute, bowl | Conveyor height & bottle height adjustable. |

| Safety / Finish Standards | GMP / cGMP compliant, SS cladding, guards, low noise | Emergency stop, sensors, hygienic finish. |

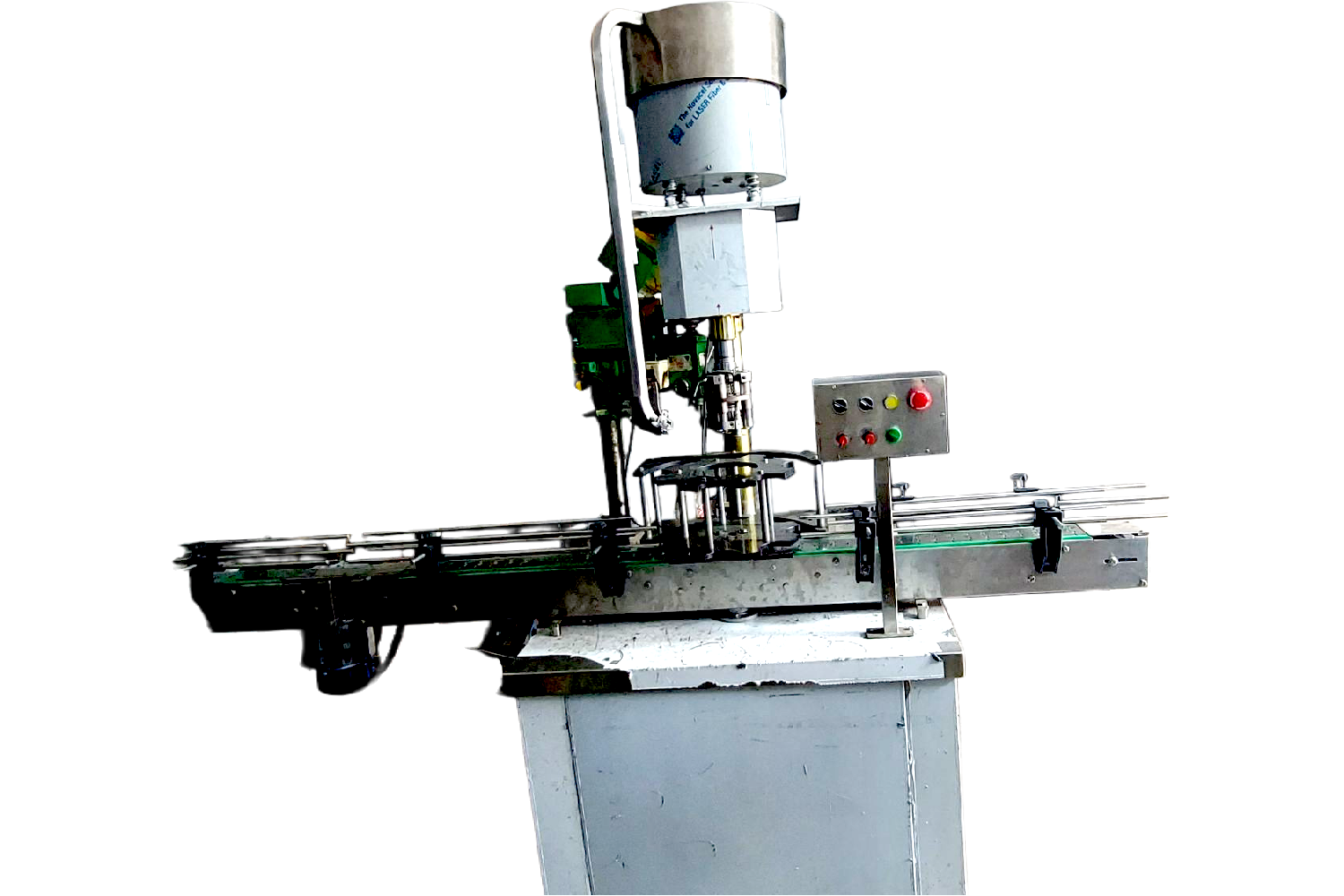

Automatic Crown Capping Machine

| Parameter | Typical Value / Range |

|---|---|

| Production Speed | 30 - 120 bottles/min (BPM), depending on number of heads |

| Bottles per Hour | 1,800 - 7,200 BPH depending on configuration |

| Number of Capping Heads | 1, 4, 6, 8, 10, 12 heads typical |

| Bottle Diameter | ~25 mm up to ~100-130 mm (depends on machine & change parts) |

| Bottle Height | ~50 mm up to ~320-350 mm depending on model |

| Cap Diameter | ~19-38 mm typical; up to ~65 mm with change parts |

| Cap Height (Skirt) | ~15-18 mm approx. for standard crown caps |

| Power Supply | 415 V / 3 phase / 50 Hz; single phase for small machines |

| Motor Power | ~1-2 HP for small machines; higher for multi-head models |

| Drive Type | AC motor with VFD; synchronized drives for turret, conveyor, star wheel |

| Frame / Material | SS 304 body/frame; SS contact parts; UHMW PE / Delrin wear parts |

| Conveyor Height | Adjustable ~800-900 mm from floor |

| Machine Dimension | Varies with heads; single head ~1.5-2 m length; multi-head longer |

| Weight | 200-500 kg (single head); multi-head heavier |

| Sensors & Safety | “No bottle, No cap” system; cap/bottle sensors; safety guarding; auto stop; overload clutch |

Common Features

- Adjustable for different bottle sizes using change parts (star wheel, guides, chutes).

- Vibratory bowl or hopper cap feeder for orienting & supplying caps.

- Star wheel/indexing mechanism to position bottles under capping heads.

- Variable sealing pressure & torque for proper crown crimping.

- Touchscreen / HMI or operator panel for control, speed adjustment, diagnostics.

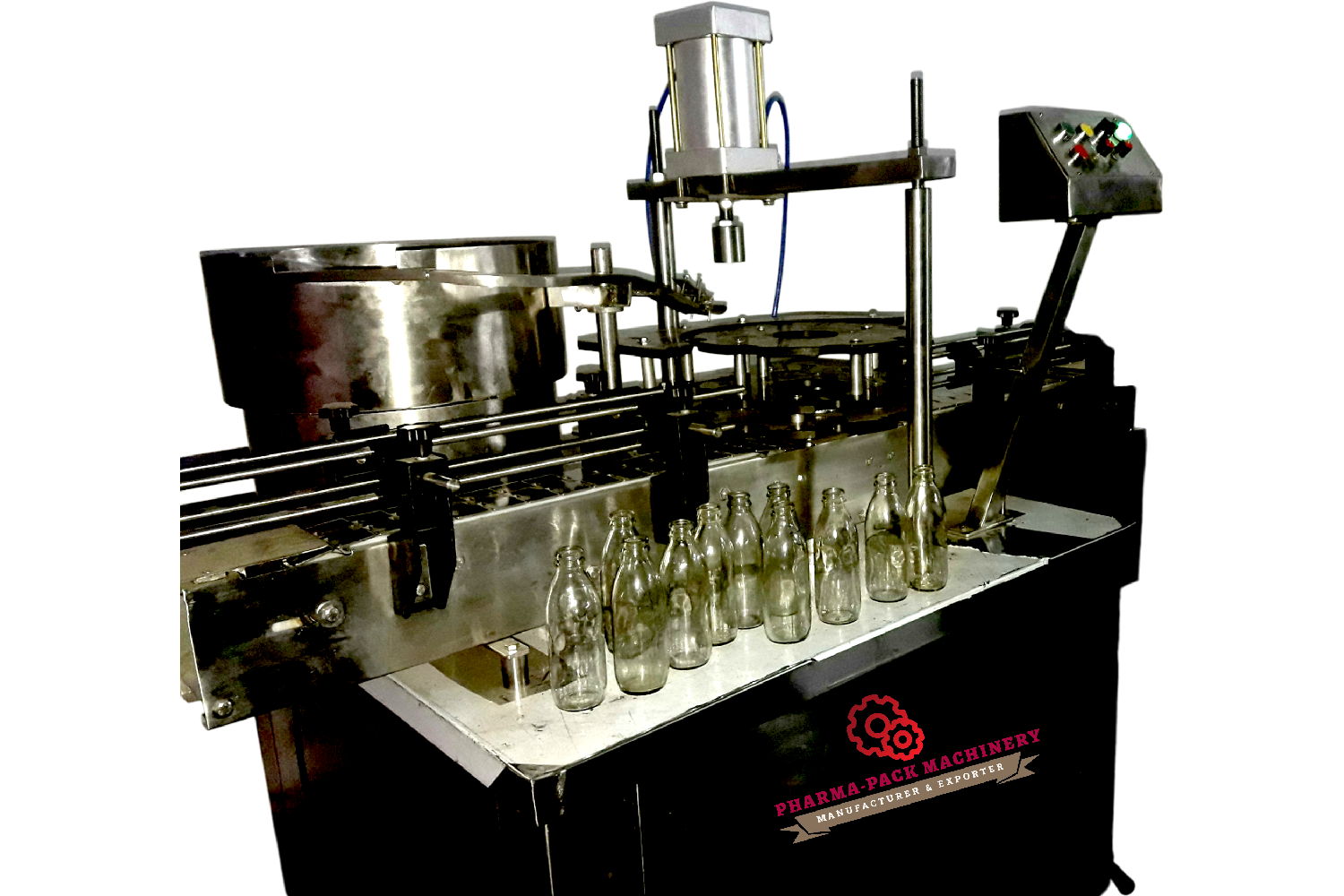

Automatic Lug Capping Machine — Typical Values (Single Head)

Reference: typical specification summary for a single-head lug / twist-off capper.

| Parameter | Typical Value / Notes |

|---|---|

| Output / Speed | ~ 30-40 bottles / minute → ~ 1,800-2,400 bottles / hour |

| Sealing Head(s) | 1 head (single-head machine) |

| Cap Type | Lug / Twist-off caps |

| Cap Size Range | Approx. Ø 20-50 mm (height ~ 10-20 mm). Change parts may be needed for larger or special caps. |

| Bottle Diameter / Shape | Round bottles: ~ Ø 20-100 mm. Flat / square possible with change parts. Typical height: ~ 50-250 mm. |

| Material of Construction | Stainless steel (SS304) main frame; contact parts SS or UHMW-PE / hard chromium plating depending on design. |

| Power Supply / Motor | ~1 HP motor; commonly 415 V / 50 Hz (three-phase) in many Indian machines. Some single-phase configurations exist. |

| Air / Pneumatic Requirement | If pneumatic components used (clutch, etc.): ~4-6 bar compressed air. |

| Conveyor Height | Adjustable; around 850-900 mm common; tolerance ± 50 mm. |

| Machine Dimensions | Varies by design. Example: length ~1.5-2.2 m, width ~0.8-1.0 m, height ~1.8-2.3 m (depends on accessories). |

| Weight | Approx. 300-400 kg for single-head machines (depends on frame and components). |

| Changeover Time / Parts | Cap dies, delivery chutes, star wheels / feed worms may need swapping when changing bottle or cap size. |

| Control Features | “No bottle, no cap” interlock; torque adjustment; VFD (variable speed drive); bottle counter; sensors to detect caps and bottles. |

You can edit the table structure or add extra columns (e.g., tolerances, change part IDs, lead times) as needed.

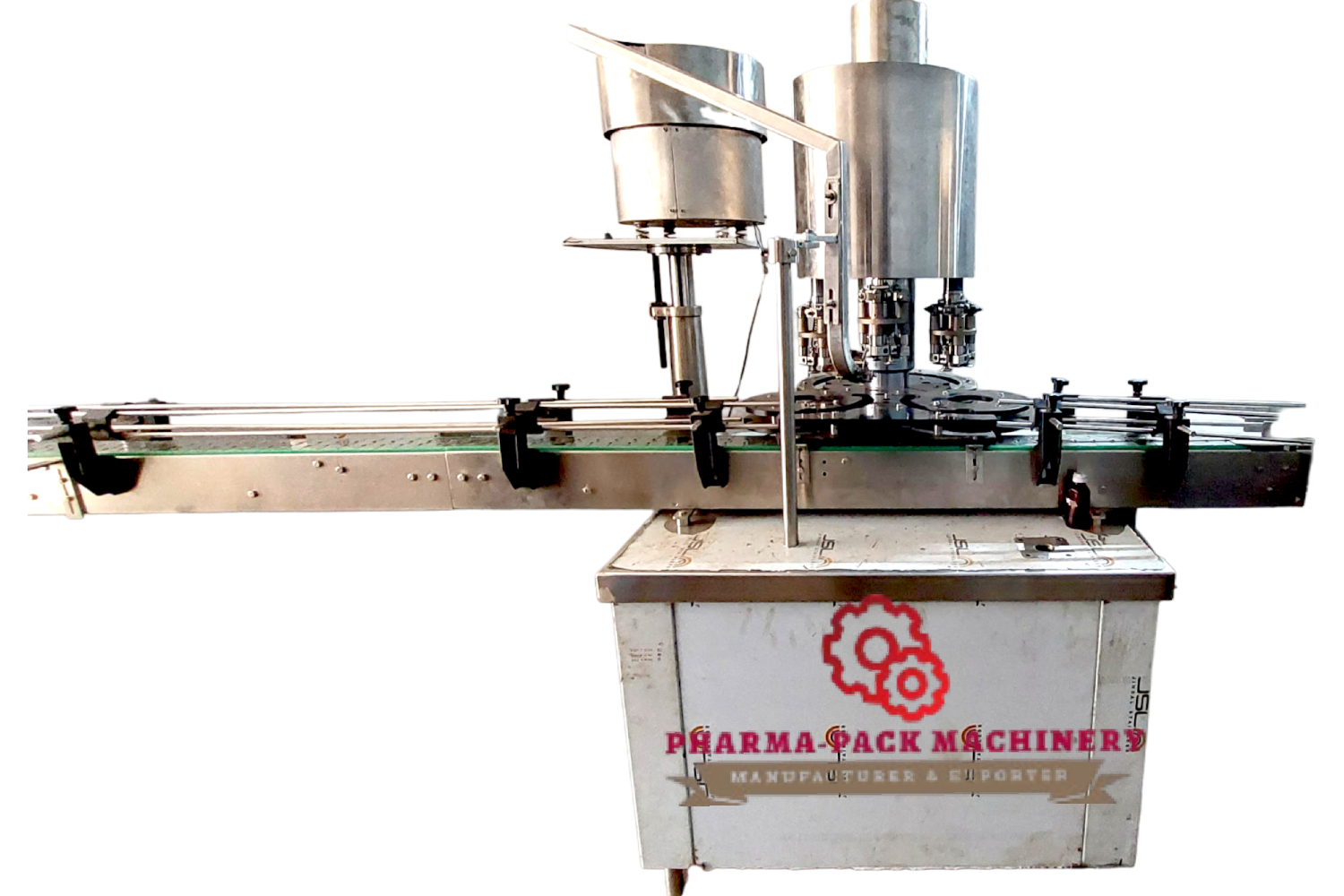

Automatic Multi Head Screw/ROPP Cap Sealing Machine

Specification Summary — Typical Ranges and Values

| Parameter | Typical Range / Values |

|---|---|

| Number of Sealing Heads | 1, 4, 6, 8, 12 heads depending on capacity needed. |

| Output (Bottles per Minute / Hour) |

~40-50 BPM for single/4-head machines, up to ~150-200 BPM for 8+ heads. Hourly figures: 3,600-12,000 bottles/hour for typical 4, 6, 8 head machines. |

| Bottle / Container Size Range |

Diameter ~20 mm up to ~65-100 mm (depending on change parts). Height up to ~200+ mm depending on design. Customization possible. |

| Cap (ROPP/Screw) Size | Diameter ~20-40 mm (change parts may be required). |

| Conveyor Height | Adjustable; ~750-900 mm (≈ 800 ± 50 mm) to match upstream/downstream machines. |

| Power Supply / Motor | 1-3 HP motors for main drive, 3 phase 440V / 415V / 50 Hz; auxiliary motors for conveyors, cap feeders, etc. |

| Machine Dimensions & Weight |

Length ~1.4-3.0 m; width ~0.8-1.1 m; height ~1.8-2.2 m. Weight ~500-1,400 kg depending on size and number of heads. |

| Change Parts / Format Change | Star wheel, feed worm, guide rails, chute, pressing head, etc., must be changed for different bottle/cap sizes. |

| Salient Features / Safeties |

• No Bottle-No Cap interlock system • Adjustable sealing pressure for cap thickness • Vibratory/mechanical bowl or chute for cap orientation • SS 304/316 contact parts with hygienic finishes • Adjustable conveyor height for easy integration |

| Utilities / Others |

• Electrical: 1-phase / 3-phase power (commonly ~415 V / 50 Hz) • Air supply if required (for some pneumatic components) • Optional safety guarding/enclosures (acrylic/glass) • Remote sensors and monitoring systems available |

Note: Values are indicative and may vary depending on machine design and manufacturer.

Semi-Automatic Screw / ROPP Capping Machine

Bootstrap-styled specification tables and key features for product pages, catalogues or technical sheets.

- Designed to seal ROPP caps, screw caps (plastic or metal), aluminium caps, etc.

- Typically has 1 capping / sealing head.

- Manual feeding / unloading of bottles (semi automatic).

- Adjustable height for bottle placement to accommodate different bottle heights.

- Change parts / cap dies for different cap diameters.

- Variable sealing pressure / torque control.

- Built to GMP / sanitary standards (SS304 options available).

- "No bottle, no capping" safety interlock.

- Vibratory bowl or cap feeder (optional).

- SS304 stainless steel construction for hygiene.

- Adjustable guides and head height gauge.

- Low noise, low power consumption.

Typical Technical Specifications

| Specification | Range / Typical Values |

|---|---|

| Output / Speed | ~10-25 bottles per minute (common models ~20-25 BPM) |

| Cap Diameter | ~18 mm up to ~50-70 mm (depends on change parts) |

| Bottle Diameter | Typically up to ~90-100 mm; smaller bottles supported |

| Bottle Height | Roughly ~50-300 mm (varies by model and cap type) |

| Drive / Power | ~0.5-1 HP motors common; electrical: single phase 220-240V or 3-phase 380-415V, 50 Hz |

| Overall Dimensions (example) | ~(L X W X H) 700-1000 mm X 600-800 mm X 1300-1600 mm |

| Weight | ~100-250 kg depending on frame, materials, and options |

| Construction | MS painted frame with SS304 contact parts (SS full-frame optional) |

| Safety | Interlocks, emergency stop, and safety guards as per local regs |

Notes: Values above are typical ranges. Exact specs vary by model & manufacturer — use this table as a starting template for product datasheets or web listings.