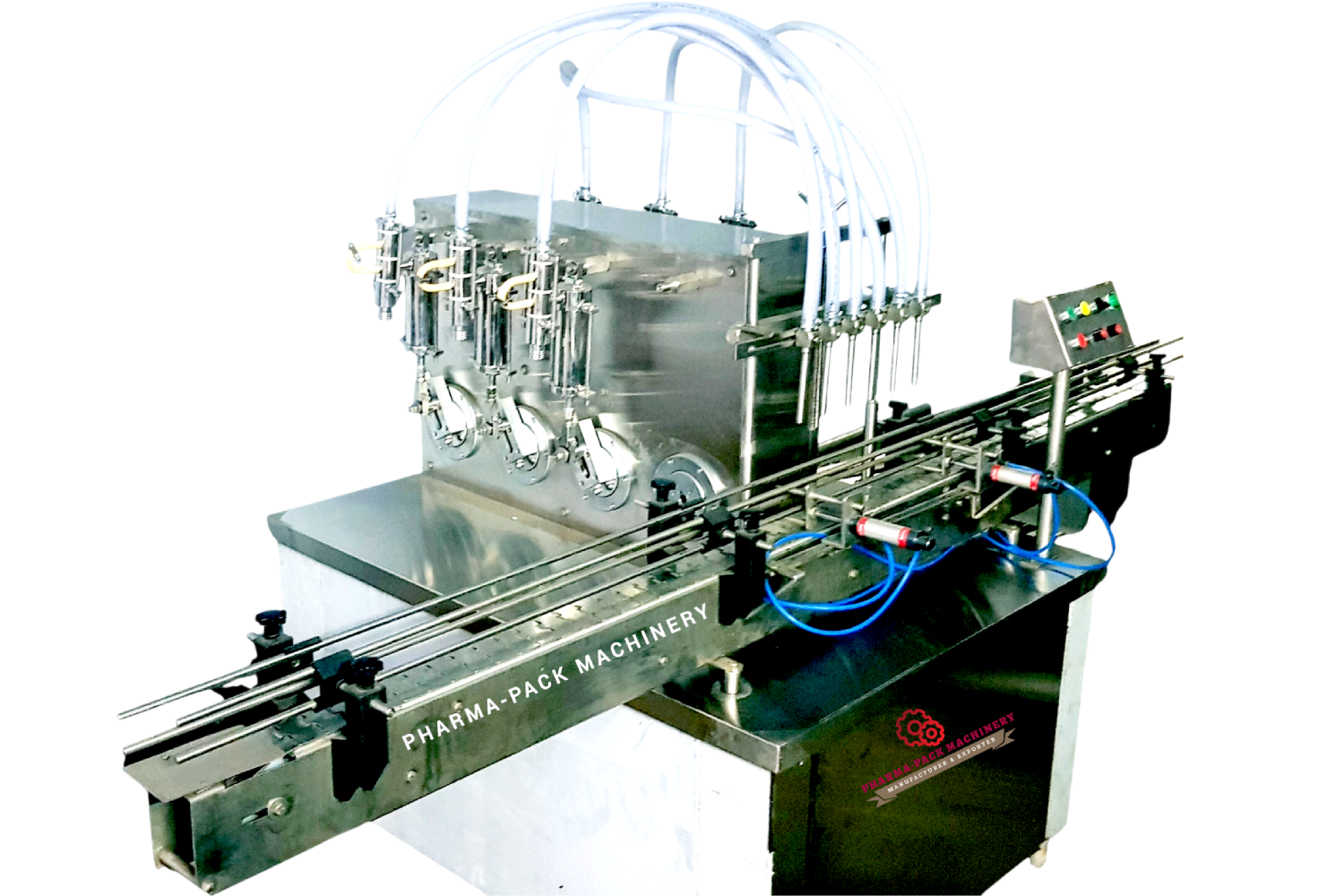

Automatic Servo PLC Base Liquid Bottle Filling Machine

Technical Specifications

| Filling System | Gear Pump Controlled by Servo Motor (Schneider/Allen Bradley) |

|---|---|

| Servo Motor | 400wt to 750wt |

| Production Speed | Depends on Number of Filling Heads, Liquid Foam, Volume, Neck Size |

| Available Machine Variants | 4 Head / 6 Head / 8 Head / 10 Head |

| Working Direction | Left to Right |

| Suitable Products | Free Flow Liquid |

| Containers | HDPE / PET / Glass / Metal Tin / Aluminum Bottles |

| Volume Capacity | 5ml to 200ml / 50ml to 5 Liters / 10 & 15 Liters |

| Volume Adjustment | PLC + HMI One-Time Setting (Schneider / Allen Bradley) |

| Drip Prevention | Special Nozzle with NRV Valve |

| No Bottle No Filling | Sensor Based |

| Bottle Stopper | Pneumatic Based (Techno / Janetic) |

| Collection Tray | Pneumatic Based (Techno / Janetic) |

| Up/Down Movement | Pneumatic Based (Techno / Janetic) |

| Filling Accuracy | ± 0.2% to 0.5% |

| Working Height | 860mm (± 50mm) |

| Machine Weight | Approx. 750 kg |

| Machine Dimensions | Depends on Filling Head Model |

Material of Construction

| Main Frame | SS ANGEL SS 304 Heavy Duty |

|---|---|

| Conveyor | Complete SS 304 |

| Contact Parts | SS 316L (Contact) / SS 304 (Non-Contact) |

| Star Chain | 97mm Pitch, 3.5", Thickness 3mm, SS 304 |

| Conveyor Motor | 0.5 HP, 1440 RPM (Rotomotives / Crompton / Bonfiglioli) |

| Bearings | SKF / NACHI USA / TIMKEN USA |

| Plating | Zinc / Hard Chrome / Blackening (Where Applicable) |

| Inlet & Outlet Pipe | Branded House Pipes |

| Bypass Pipe | Silicone Pipe |

| Material Collection Tray | Complete SS 304 |

| Cabinet Options | SS Structure / Acrylic Cover |

| Emergency Stop | Emergency Switch Button on Conveyor |

Electrical & Pneumatic Components

| Gear Box | Bonfiglioli / Rotomotives / Warm |

|---|---|

| VFD Drives | Schneider / Allen Bradley / Delta |

| HMI + PLC | Delta / Schneider / Panasonic |

| Electric Wiring | Ferrule Numbered with Proper Marking |

| Level Sensor | Leuze / Sick / Panasonic |

| Proximity Sensor | Autonix / Pulset |

| Wires & Cables | RR Company |

| Power | 2 HP to 3 HP, 230V, Single Phase |

| Compressor Air Required | 6 Bar Pressure, 0.5 CFM |

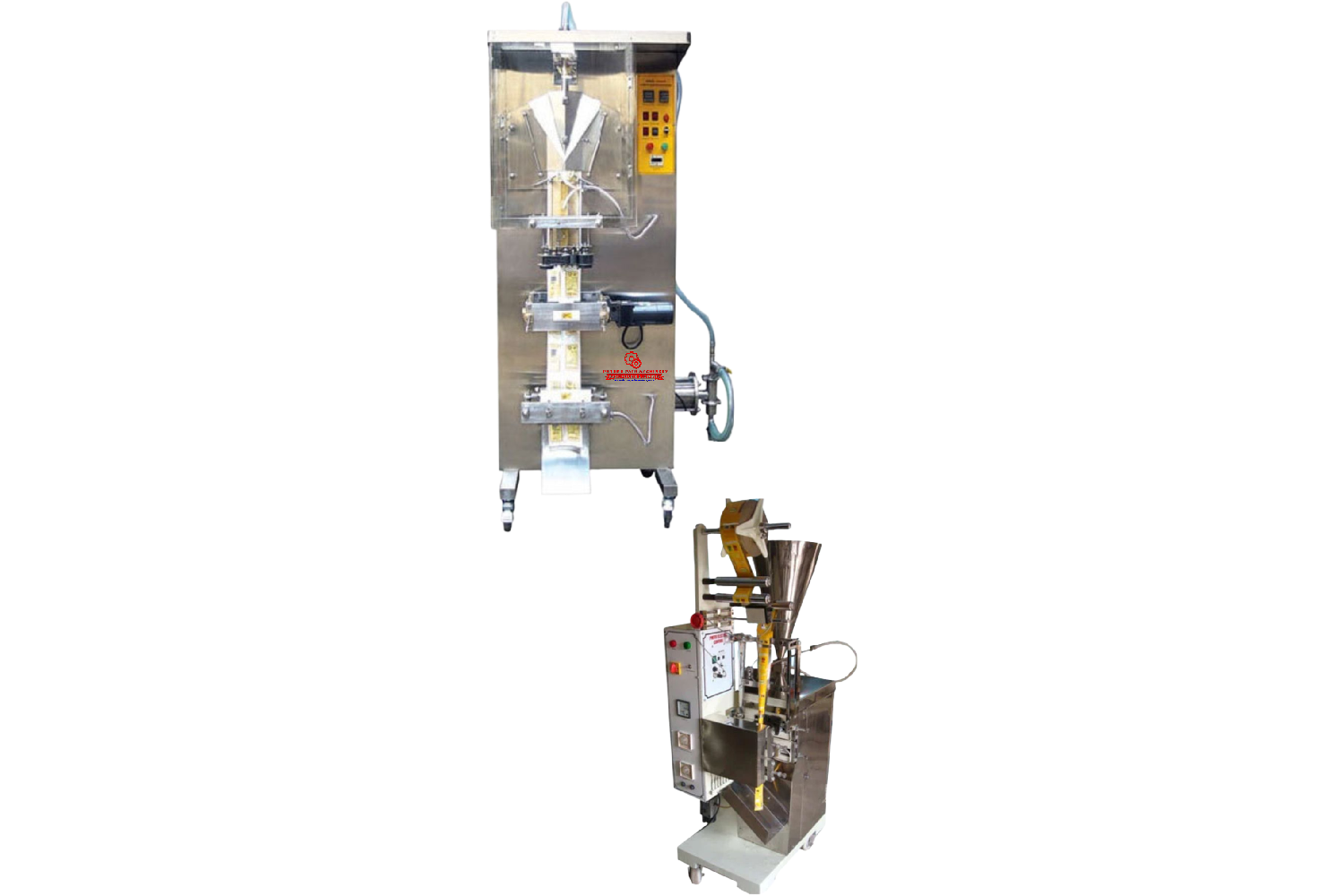

Automatic Pouch Filling-Sealing Machine (FFS - Edible Oil Packing - Open Body)

Open Body Automatic Liquid Packing Machine for Oil, Edible Oil, Soya Oil, Palm Oil, Ghee, Mangoras, and other liquids. Available in Center Seal and Three-Side Seal models. Features a double sealing system suitable for oil and ghee, I-mark sensor for accurate cutting, and supports Nylon-based LD film (up to 100 microns).

Product Features

- Online counting system

- Easy to operate & maintain

- Digital controller

- Pouch length adjustable by programmer controller

- High accuracy sealing & cutting impression

- Low waste disposal

- Fully automatic, compact, and robust design

Technical Specifications

| Capacity | 200-1000 ml |

|---|---|

| Filling System | Filling by Gear Pump |

| Packing Material | Low Density (L.D) Polyethylene Film |

| Type of Sealing | Center Seal (Three-Side Seal Also Available) |

| Film Size | 325 mm Width |

| Operating System | Mechanical Base |

| Speed | 800 to 1200 Pouches/Hr (Varies with Product & Filling Range) |

| Pouch Pulling | Pouch Pulling by Electronic Motor |

| Power | ½ HP Motor, Single Phase |

| Sealing Type | Impulse Bar |

| Photocell System | Available |

| Batch Coding System | Optional (As Required) |

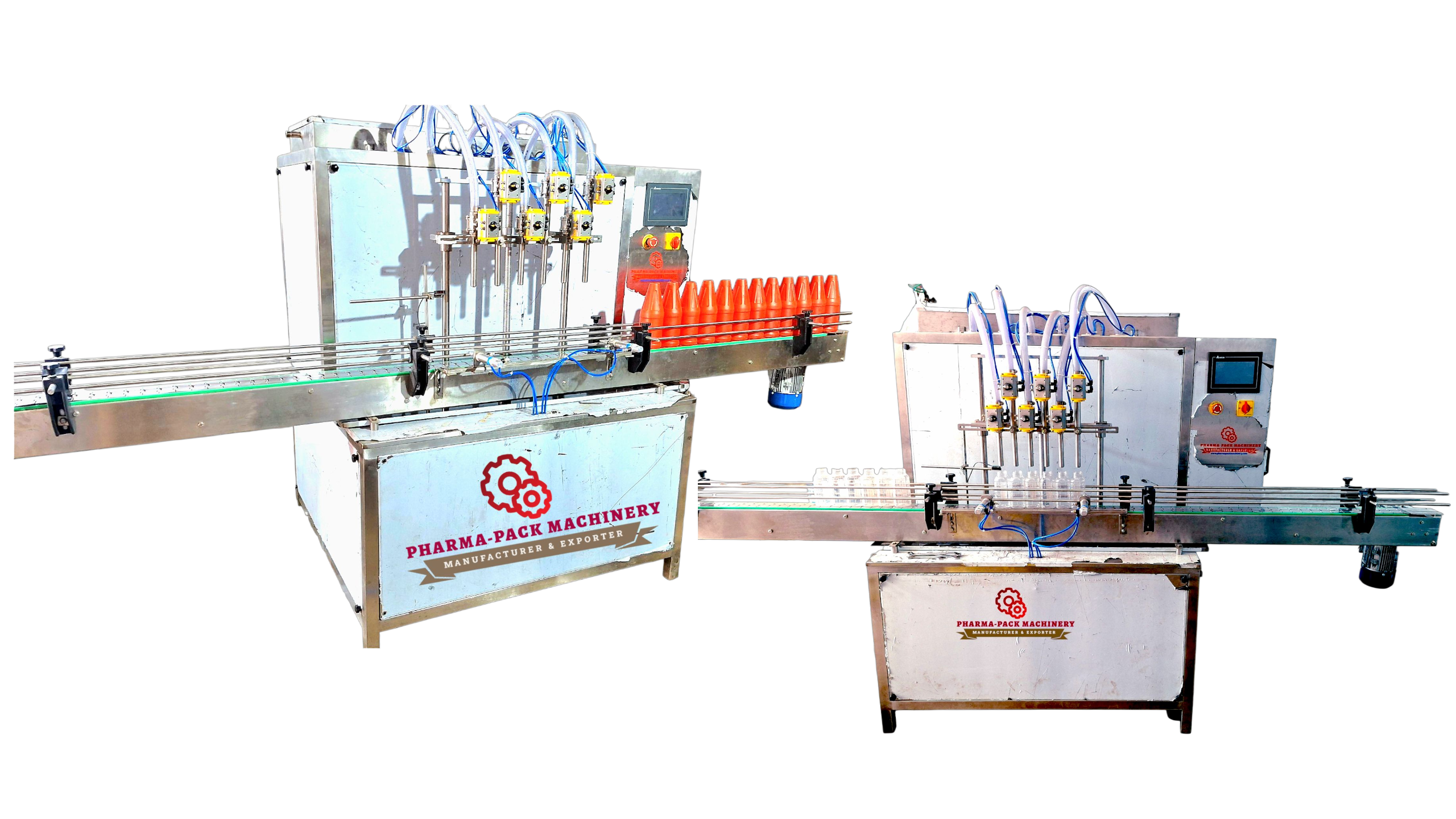

Automatic Volumetric Liquid Bottle Filling Machine

This volumetric piston-based filling machine ensures high accuracy, low foaming, and consistent performance across a wide range of liquid products. Designed with hygiene, durability, and productivity in mind, it supports fast changeovers and is suited for industries from pharmaceuticals to cosmetics and food.

Key Features

- ±1% fill accuracy using piston-syringe assembly

- “No Bottle, No Fill” system ensures precision and cleanliness

- Contact parts: SS 316; Non-contact parts: SS 304

- Diving nozzle mechanism to reduce foaming

- Interchangeable syringes (10 ml - 1000 ml)

- Left-to-right linear workflow for inline integration

- Rigid vibration-free construction for stable performance

- Elegant control panel with intuitive access

- Quick changeovers with modular parts

Model Comparison

| Model | No. of Syringes | Output/Hour | Fill Volume Range |

|---|---|---|---|

| PPMVFM-40 | 4 | 2200-2400 | 5 ml - 1000 ml |

| PPMVFM-60 | 6 | 3000-3600 | 5 ml - 1000 ml |

| PPMVFM-80 | 8 | 4000-4800 | 5 ml - 1000 ml |

| PPMVFM-100 | 10 | 5000-6000 | 5 ml - 1000 ml |

Technical Specifications

| Construction | Rigid vibration-free stainless steel body |

|---|---|

| Contact Parts | SS 316 |

| Non-Contact Parts | SS 304 |

| Main Motor | 2 HP - 5 HP (Depending on Model) |

| Electric Power | 440V, 3 Phase, 50Hz / Optional 230V, 1 Phase |

| Bottle Diameter Range | 30 - 100 mm |

| Drive System | AC Frequency Drive for Motor and Conveyor |

| Conveyor Type | Slat Conveyor, 6 ft - 10 ft (Height Adjustable: 800mm - 900mm) |

| Liquid Collection | Long SS tray with outlet under conveyor |

| Stopper & Nozzle | Pneumatically Controlled |

Industries Where It's Used

- Pharmaceuticals

- Syrups / Cough Medicines

- Oral Liquids / Nutraceuticals

- Cosmetics & Personal Care

- Shampoos / Hair Oils / Lotions

- Liquid Soaps / Serums

- Food & Beverages

- Juice / Flavored Water

- Sauces / Edible Oils / Vinegar

- Chemicals

- Disinfectants / Pesticides / Solvents

- Cleaning Agents

- Ayurvedic & Herbal Products

- Herbal Tonics / Extracts / Oils

Semi Automatic Volumetric Liquid Filling Machine

The Semi-Automatic Volumetric Liquid Filling Machine offers precision liquid filling through piston-based or cylinder-driven volumetric systems. Designed for SMEs, labs, and light industrial use, these machines are ideal for a wide range of liquid viscosities with excellent changeover efficiency and fill accuracy.

Key Features

- Filling volume from 5 ml to 1,000 ml (extendable to 5+ litres)

- Filling accuracy: ±1% standard, up to ±0.5% for premium models

- Output: 600 - 2400 containers/hour (10-40 BPM depending on viscosity)

- Available with 1 to 4 filling heads for increased throughput

- SS304 body and SS316 contact parts; fully GMP-compliant

- Manual or foot pedal operation; fill volume adjustable via VFD or dial

- Power: 230 V single-phase or 415 V three-phase; 0.5-1 HP motor

- Air supply required (4-6 bar) for pneumatic nozzle actuation

- Compact design: 900X900X1050 mm; ~95-120 kg weight

- Fast changeovers using modular syringes and adjustable dosing blocks

Summary Specification Table

| Feature | Typical Specification |

|---|---|

| Fill Volume | 5 ml - 1,000 ml (extendable to 5 L+ via change parts) |

| Filling Accuracy | ±1% (standard); ±0.5% for premium models |

| Speed / Output | ~700-2,400 containers/hour (10-40 BPM) |

| Number of Filling Heads | 1-4 heads typically; custom options available |

| Construction | SS304 body; SS316 contact parts; GMP-compliant |

| Controls | Manual/foot pedal operation; VFD or manual volume/speed control |

| Power Requirements | 230 V/415 V, 0.5-1 HP motor; pneumatic versions require 4-6 bar air |

| Size & Weight | Approx. 900X900X1050 mm; ~95-120 kg |

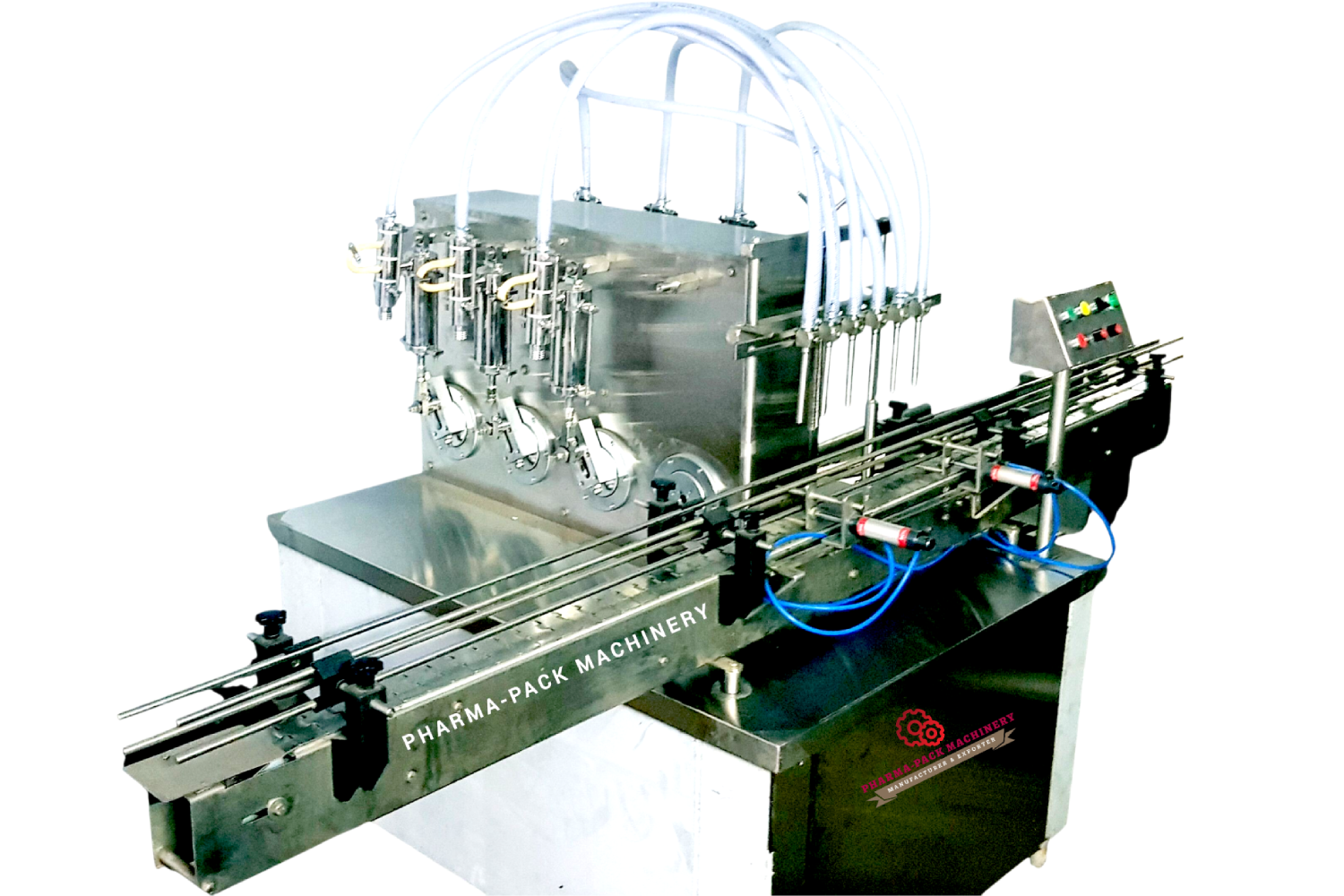

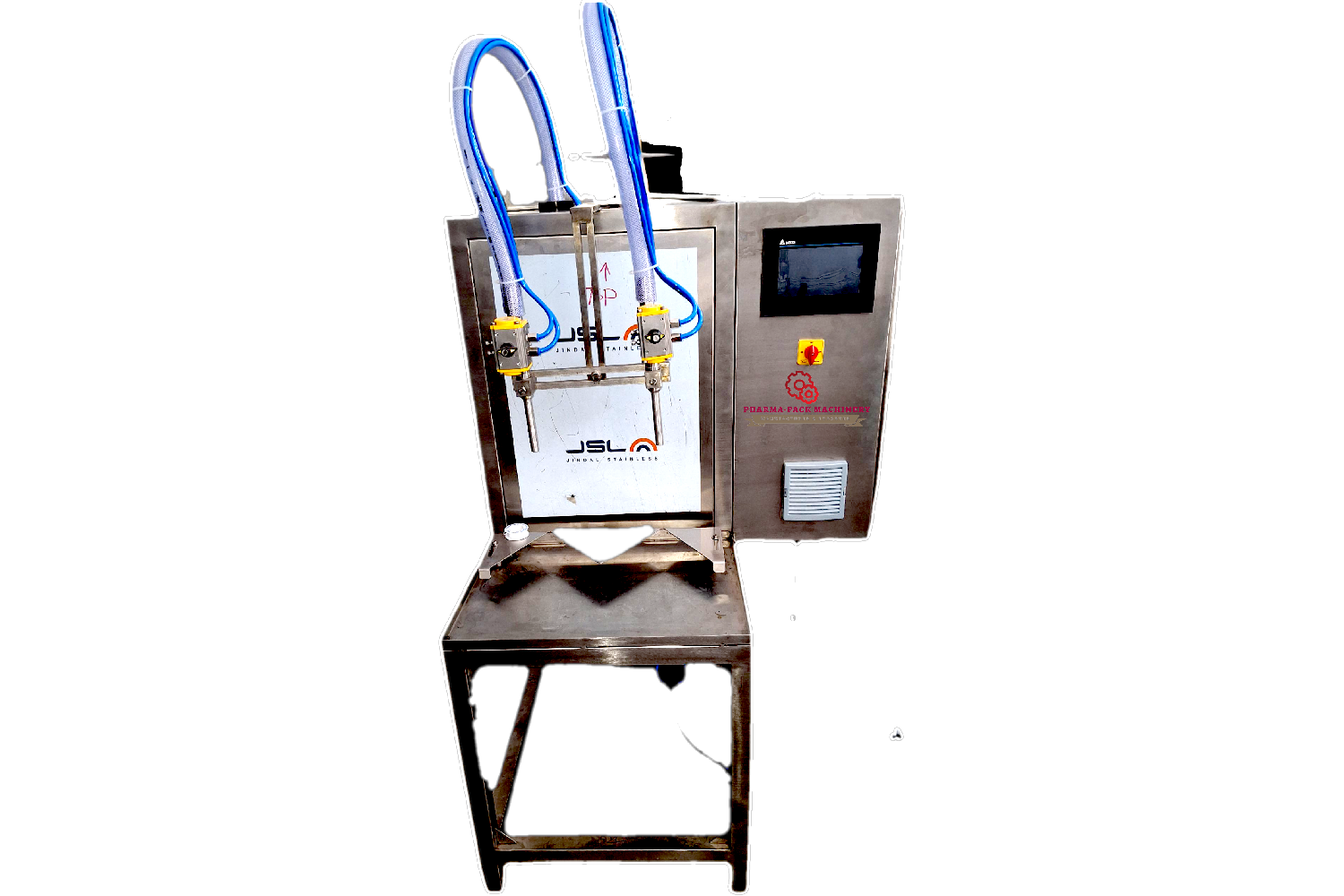

Semi-Automatic 2 Head Servo Base Liquid Bottle Filling Machine

Key Features

- Two filling heads (nozzles) enabling simultaneous filling of two bottles.

- Servo motor-based metering / gear pump or piston pump system for precise, repeatable filling volume.

- Semi-automatic: operator places bottles; machine fills; basic pneumatic or manual/sensor-assisted bottle stopping & nozzle actuation.

- “No bottle, no fill” safety/sensor arrangement to avoid wastage.

- Diving or reciprocating nozzles to reduce splashing/foaming (for more viscous or foamy liquids).

- Change parts or modular setup for different fill volumes (change nozzle, syringe/piston size, etc.).

- Stainless steel (SS 304 or SS 316) contact parts; other structural parts SS cladding or powder-coated mild steel.

- Basic user interface for setting fill volume; may include PLC/HMI in higher-end models.

Technical Specifications

| Parameter | Typical Values / Range |

|---|---|

| Fill Volume Range | ~ 5-10 ml up to ~ 1000-5000 ml (for 2 head units) depending on change parts |

| Accuracy / Tolerance | ± 0.2% to ± 0.5% (on a single dose) depending on liquid, machine tuning |

| Output Rate (two heads) | ~20-25 bottles/min (depending on fill volume, viscosity, bottle shape) for free-flow liquids; lower for viscous liquids |

| Power Supply | 1 Phase & 3 Phase, ~ 220-415 V, 50-60 Hz; motor power 0.5-3 HP or more depending on load |

| Air / Pneumatic Requirements | ~ 4-6 bar compressed air for bottle stopping, sensors, and nozzle actuation |

| Machine Dimensions / Weight | ~ 1-2 m (L), 0.7-1.2 m (W), 0.8-1.8 m (H); Weight: ~ 100-600 kg or more |

| Material of Construction | SS 316 (contact parts), SS 304 (non-contact), frame with SS cladding or powder-coated MS; PTFE/silicone hoses/valves |

Automatic Milk Pouch Filling Sealing Machine (FFS)

| Parameter | Typical Range / Value | Notes / Comments |

|---|---|---|

| Pouch (Bag) Capacity / Volume | 200 ml - 1000 ml (or more depending on model) | Customizable, e.g. 200-500 ml small pouches, 1 L large pouches |

| Pouch Size (Width x Length) | ~140-160 mm width; length varies (e.g. 150x165 mm for 500 ml, 150x255 mm for 1 L) | Must match film width; pouch design influences sealing type & dimensions |

| Film / Packaging Material | LDPE / multilayer LDPE / heat sealable laminated film; 60-100 µm typical, up to 190 µm | Film strength, sealability & food safety critical |

| Type of Sealing | Center seal, 3-side seal, 4-side seal; impulse sealing bars | Choice depends on strength, aesthetics, leakage risk, pouch shape |

| Filling Mechanism | Gear pump / volumetric pump (servo control optional) | Pump mechanism better for liquids like milk than cup fillers |

| Capacity / Speed | 800-1500 pouches/hr (200-500 ml); 30-80 pouches/min for small sizes | Speed decreases with larger pouch size; film change causes downtime |

| Power & Electrical Requirements | Single phase 220-230 V AC; some models 3 phase 415 V; ~2-8 kW | Check heater load; depends on size & speed |

| Compressed Air / Utilities | ~6 kg/cm² (0.6 MPa) air; cooling water ~50-150 L/hr | For sealing, film cooling, pneumatic actuators |

| Machine Dimensions & Weight | Width 0.75-1.8 m; Depth 0.5-1.5 m; Height 1.5-2.5 m; Weight 200-800 kg | Plan workshop space & floor loading accordingly |

| Accuracy / Tolerance | ±2-5 ml (typical) | Depends on pump & control system; important for regulations |

| Control & Automation | PLC / microcontroller, HMI, sensors (photo cell, film alignment) | Automatic stop for faults, film runout, misalignment |

| Construction & Hygiene | Food-grade SS304/SS316 contact parts | Sanitary design, easy cleaning, regulatory compliance |

Additional / Optional Features

- Batch / Date coding & printing on pouch

- Nitrogen flushing (for extended shelf life)

- Automatic film roll loading / unwinders

- Safety guards & emergency stop

- Leak / pouch misalignment alarms

- Automatic cut & tear notch for easy opening