Dry Injection Powder Vial Filling Stoppering Machine

Key Features

| Feature | Purpose / Importance |

|---|---|

| Powder filling mechanism | Accurate metering (volumetric, vacuum/piston/port wheel), minimal residue, consistent density. |

| Stoppering mechanism | To insert rubber (butyl, elastomeric) stoppers aseptically, firmly sealing the vial. |

| “No-Vial No-Fill / No-Stopper No-Feed / No-Stopper - Stop Machine” interlocks | Avoids wastage of powder, prevents mis-stopped vials, ensures safety & cGMP compliance. |

| Sterility & Cleanability | SS 316/316L contact parts, easy to dismantle & autoclave, minimal dust, laminar flow compatibility. |

| Accuracy & Repeatability | ±1 - ±3% depending on powder properties (bulk density, moisture, etc.). |

| Hygiene / GMP / Validation Support | Clean room compatible, GMP documentation, IQ/OQ support, material certificates. |

| Safety & Utility Features | Overload protection, vial breakage clutch, oil-free filtered air/vacuum, low humidity, safety guards. |

Typical Technical Specifications

| Parameter | Typical Values / Ranges |

|---|---|

| Production / throughput | ~20 - 240 vials/min (e.g. DRYFILL 120i ~120 vials/min) |

| Fill range (single dose) | ~50 mg - 1.5 g; up to 5-6 g with multiple dosing |

| Vial size / dimensions | 5 ml - 30 ml; diameter ~25-38 mm; height up to ~75 mm |

| Stopper size / type | Rubber stoppers ~13-20 mm (some models support 28-30 mm) |

| Accuracy | ±1% typical; ±2-3% in less favorable conditions |

| Material of construction | Powder/stopper contact parts: SS316/316L; frame SS304 |

| Utilities / Environmental |

• Electrical: 3 phase, 415V, 50 Hz • Compressed air: 2-4 kg/cm², oil-free • Vacuum: ~25″ Hg, 300-500 LPM • Humidity: ≤28-30% RH |

| Machine dimensions | ~2.5-3 m (L) X ~1-1.2 m (W) X ~1.7-2.1 m (H) |

| Weight | ~500-800 kg (small units) to >1 ton for larger machines |

Rotary Vial Washing Machine

| Feature | Description |

|---|---|

| Vial Size Range | 2 ml to 100 ml (with change parts) |

| Output Capacity | 2,600 to 9,000 vials per hour, depending on model and vial size |

| Washing Stations | 6 internal zones (18-36 jets) + 1-2 external air/water washes |

| Water Consumption | 200-550 liters per hour, depending on vial size and wash cycles |

| Air Consumption | 15-20 CFM (cubic feet per minute) |

| Power Supply | 3-phase, 415V, 50 Hz (standard) |

| Power Load | 4-7 HP (3-5.5 kW) |

| Conveyor Height | 875-950 mm (adjustable) |

| Construction Materials | SS 316L (contact parts), SS 304 (frame) |

| Control System | PLC with HMI (optional) |

| Changeover Parts | Required for different vial sizes |

✅ Key Features

- Rotary Motion: Ensures uniform washing by rotating vials during cleaning.

- Gripper Mechanism: Holds vials by the neck, minimizing contact and preventing damage.

- Multiple Wash Cycles: Internal & external washes using water and air.

- Material Compatibility: Suitable for both glass and plastic vials.

- Customizable Wash Sequences: Adjustable wash cycles for specific requirements.

- Compliance: Meets cGMP and FDA standards.

🛠️ Optional Features

- Ultrasonic Pre-Wash: Removes non-dilutable particles.

- Sterile Air Supply: For drying and preventing contamination.

- Water Recirculation System: Reduces water consumption.

- Integrated Drying Tunnel: For drying vials post-washing.

- Safety Enclosures: Protects operators and ensures hygienic operation.

Vial Aluminium Cap Sealing Machine

| Parameter | Typical Values / Range |

|---|---|

| Number of sealing heads | 1, 2, 4, 6, 8 heads (higher heads → higher output) |

| Production speed / output | ~30-50 vials/min up to 200-240 vials/min (depending on heads and vial/cap sizes) |

| Vial diameter | ~15 mm up to ~60-80 mm |

| Vial height | ~20-25 mm up to ~150-200 mm |

| Cap diameters accommodated | 13 mm, 20 mm, 25 mm, 28 mm, 30 mm, 33 mm (with change parts for different cap sizes) |

| Power requirement | ~0.5 HP up to ~3 HP depending on speed and head count; typically 3-phase, 440 V, 50 Hz (India). Some models support single phase. |

| Conveyor height | Adjustable, ~800-850 mm above floor level |

| Dimensions (L X W X H) | ~1.2-2.0 m X 0.8-1.0 m X 1.7-1.9 m (varies by model) |

| Weight | ~300-700 kg (standard) up to ~1200 kg (large GMP models) |

✅ Key Features / Functional Requirements

- cGMP compliance with SS316L contact parts and SS304 frame.

- “No vial - no cap” and “no cap - machine stop” interlocks.

- Photo sensors to detect cap presence in chute; auto stop if empty.

- Over-turn / oversize vial detection with clutch or safety device.

- Spring-loaded free spinning sealing rollers to avoid cap damage.

- Adjustable sealing pressure for different cap thicknesses.

- Variable speed control via VFD to sync with production line.

- Digital counters for sealed vial tracking.

- Optional: PLC with HMI, protective cabinet/enclosure, flip-off seal chuck.

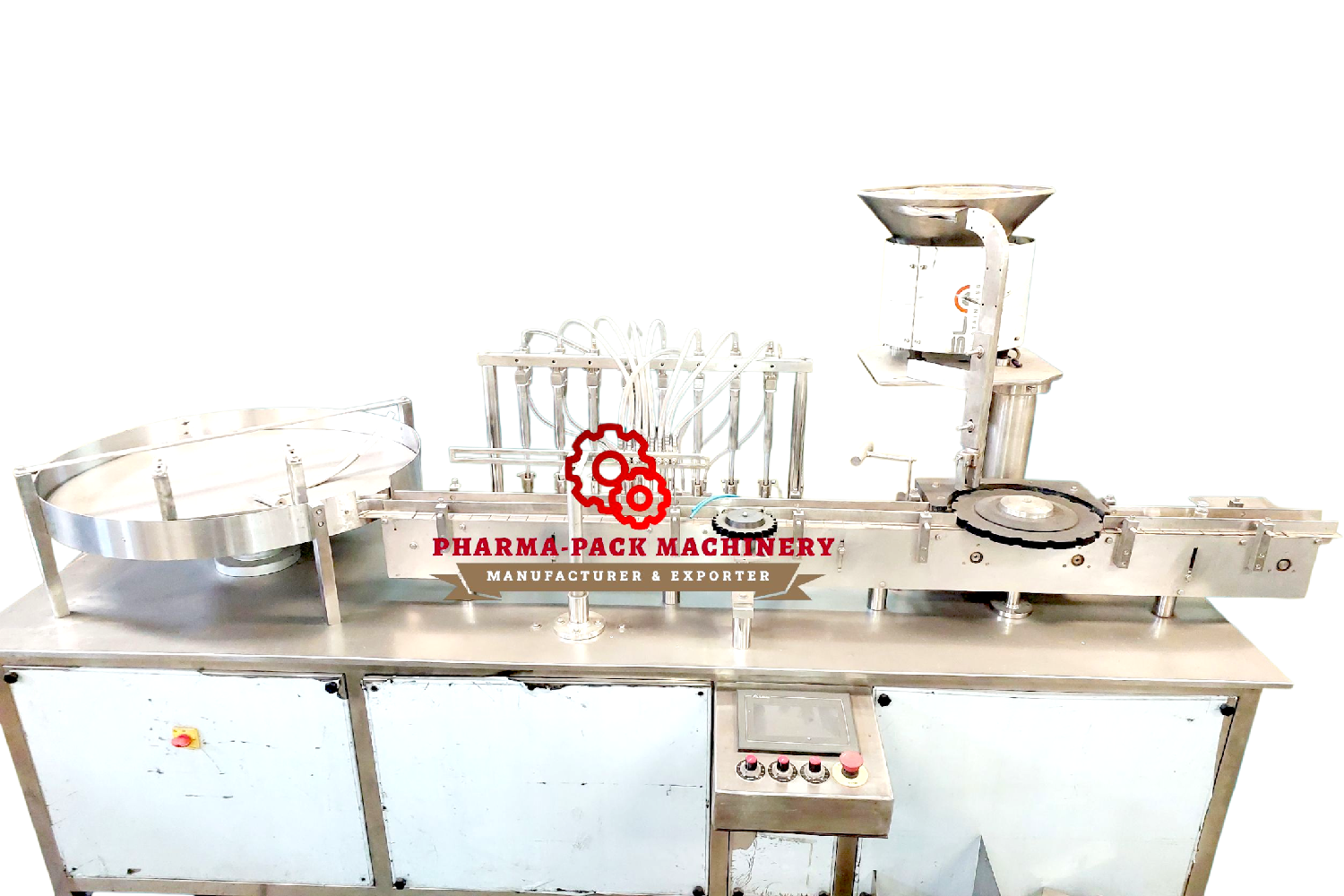

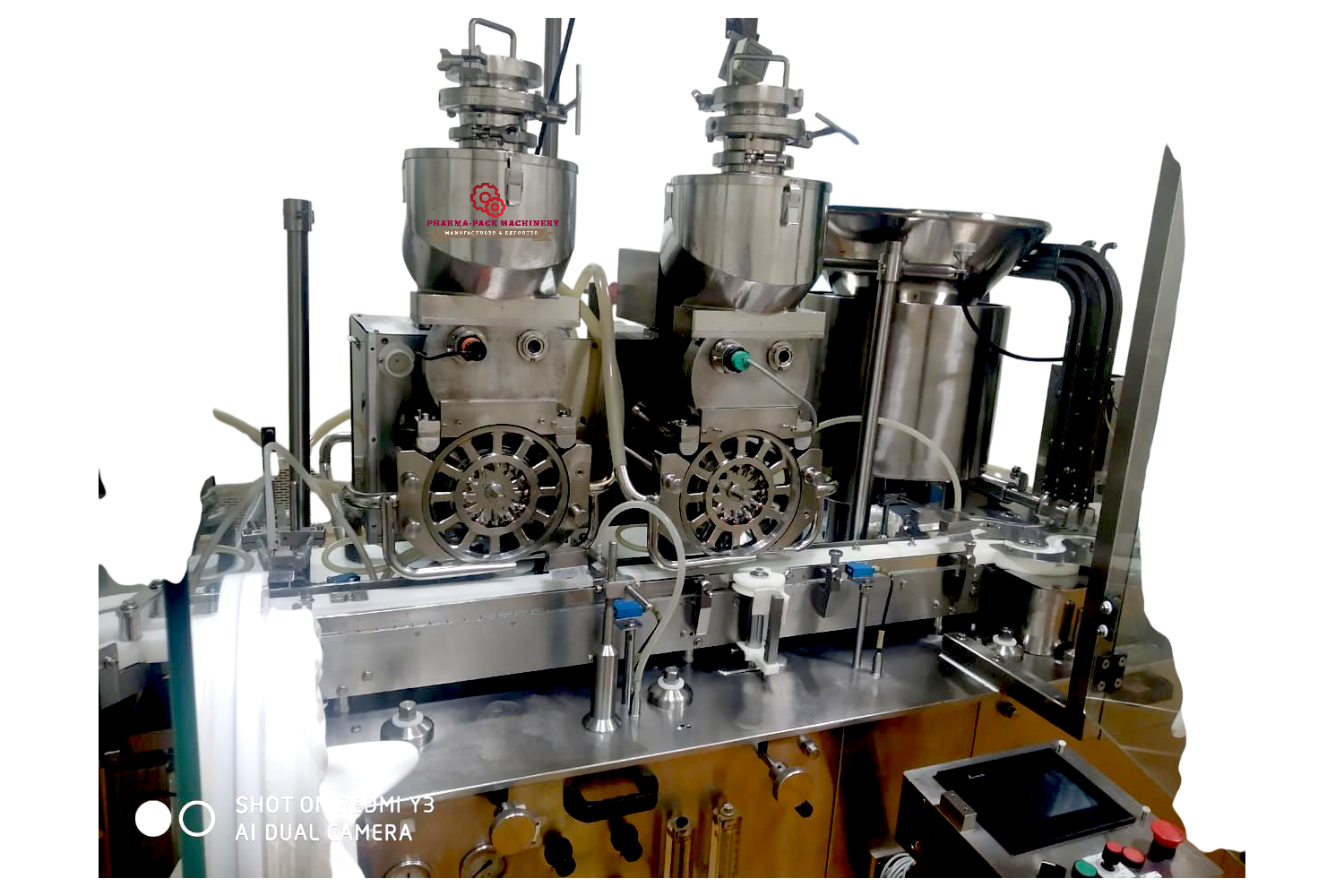

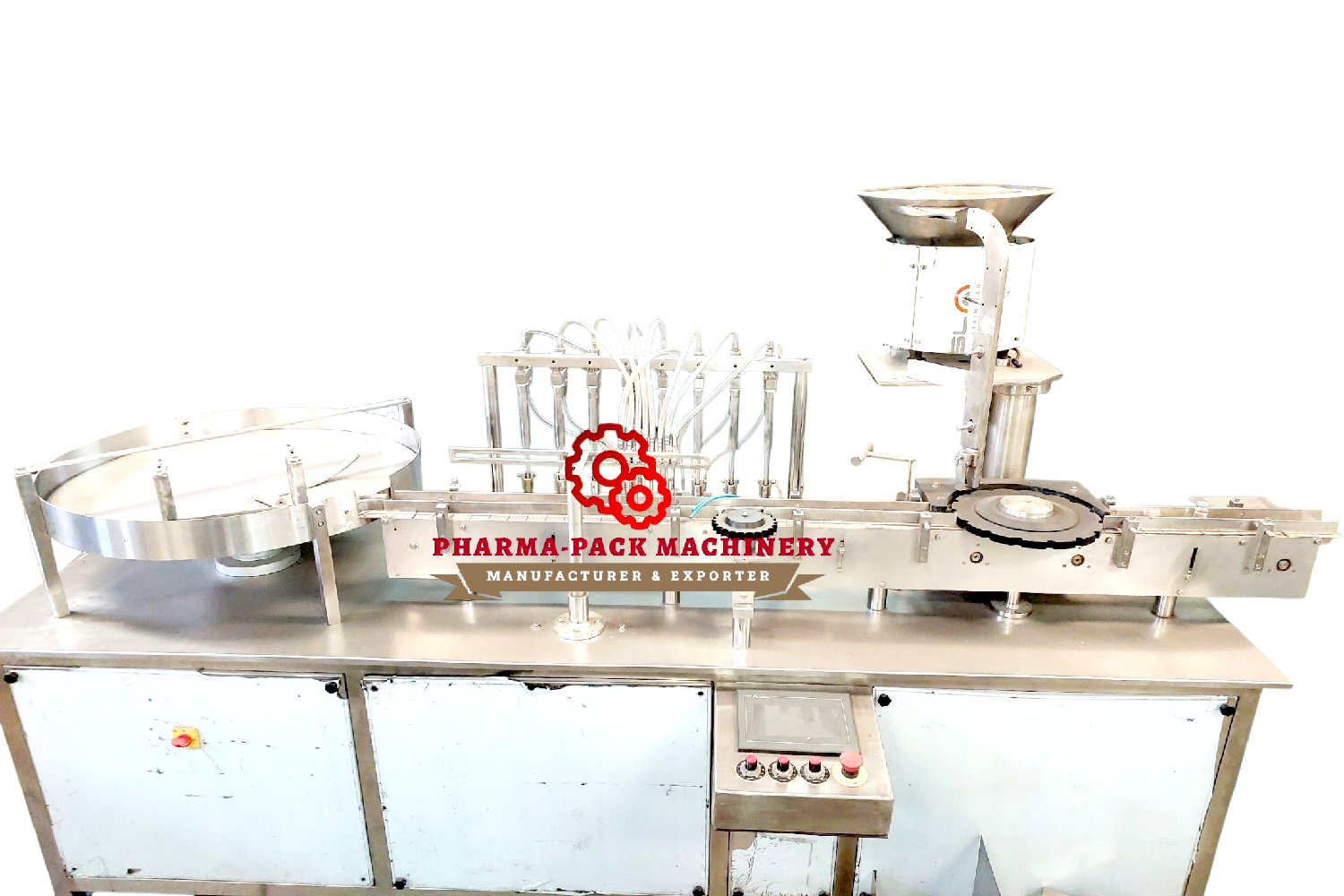

Vial Filling Stoppering Machines

| Parameter | Typical Values / Range |

|---|---|

| Number of Filling Heads / Syringes | 2, 4, 6, 8, 10, 12 heads — more heads = higher throughput |

| Fill Volume Range | ~0.1 ml to ~250 ml (change parts for small/large volumes) |

| Vial Diameter | ~15 mm to 70 mm (some machines 15-50 mm depending on design) |

| Vial Height | ~25 mm to 140 mm typical; some models max ~75 mm |

| Stopper Size / Type | Common stopper diameters: 13 mm, 20 mm, up to ~28 mm. Butyl rubber (slotted/non-slotted) |

| Accuracy | ±1 % typical; ±0.5 % for precise systems (depends on viscosity) |

| Throughput / Output | 2-head: ~20-60 vials/min; multi-head: up to 200-300 vials/min |

| Power / Electrical Specs | 3-phase, 50 Hz (small: 220 V single phase; large: 440 V 3-phase); power depends on size & heads |

| Dimensions / Footprint | 2-head: ~2-2.5 m (L) X 0.8-1 m (W) X 1.4-1.7 m (H); larger models longer |

| Material of Construction | Contact parts: SS 316L; frame: SS 304; non-toxic tubing, high-quality nozzles |

| Conveyor / Transfer Systems | Turntables/unscramblers, slat belt conveyors, star wheels, vibratory stopper bowls, pneumatic/vacuum stoppering wheels |

| Safety / Control Systems | PLC + HMI; “no vial / no stopper / no fill” sensors; E-stops; VFD speed control; diving nozzles; gassing options |