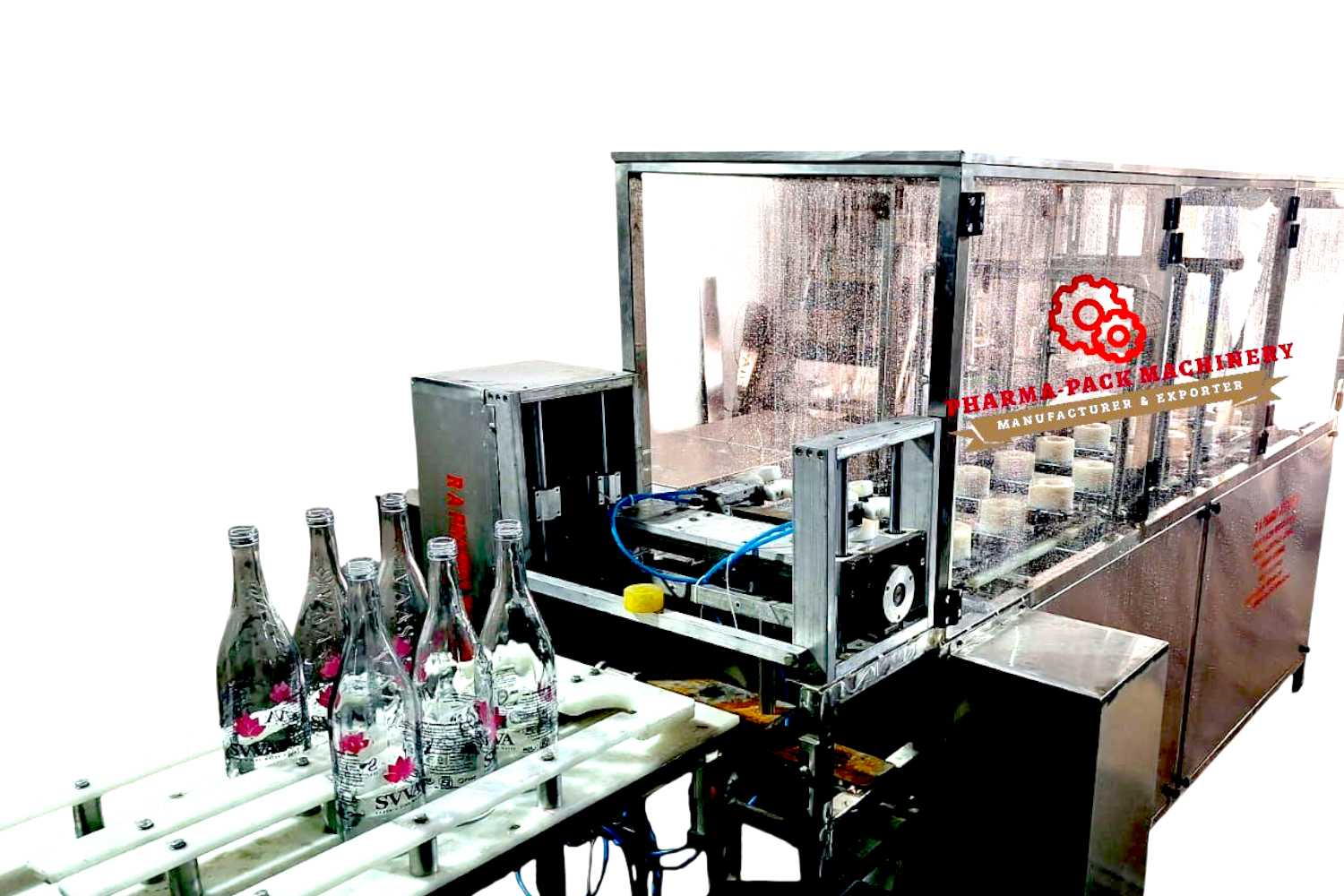

Fully Automatic Rotary Bottle Washing Machine

Machine Description

A rotary-type automatic machine designed for internal and external washing of bottles using multiple jets and washing sequences. It features an automatic bottle loading, gripping, rotating, and unloading mechanism.

Key Features

| Feature | Description |

|---|---|

| Type | Fully Automatic Rotary Bottle Washing Machine |

| Operation | Continuous Rotary Motion with Bottle Gripping & Indexing System |

| Bottle Types | Round / Flat / Square Bottles |

| Bottle Material | Glass / PET / HDPE / Plastic |

| Bottle Sizes | 30 ml to 1000 ml (customizable) |

| Washing Stations | 6 to 12 (configurable based on model) |

| Washing Media | Filtered Water, Hot Water, Air Wash, Detergent Wash, or as per client need |

| Washing Cycle | Internal + External wash with customized sequencing |

| Infeed/Outfeed | Automatic with Bottle Holders or Pucks |

| Bottle Gripping Mechanism | Rotary grippers with adjustable arms |

Technical Specifications

| Parameter | Specification |

|---|---|

| Production Capacity | 60 - 300 Bottles per Minute (varies by model) |

| Power Supply | 3 Phase, 415V, 50Hz (customizable) |

| Power Consumption | 2 - 5 kW (approx., model-dependent) |

| Air Consumption | 5 - 10 CFM @ 6 Bar |

| Water Consumption | 200 - 500 liters/hour (varies by cycle) |

| Construction Material | SS 304 / SS 316 (contact parts) |

| Control System | PLC-based with HMI touchscreen (Siemens/Mitsubishi) |

| Safety Features | Overload protection, No bottle - No wash interlock |

| Dimensions | Approx. 2000 mm (L) x 1500 mm (W) x 1800 mm (H) |

| Weight | 800 - 1500 kg (depending on model) |

Optional Features

- Online Water Recirculation System

- Automatic Bottle Loading Elevator

- Customized Washing Cycles

- VFD for Speed Adjustment

Compliance & Standards

- cGMP & FDA Compliant

- CE Certified (if exported)

- SS316 Contact Parts as per pharmaceutical standards

Fully Automatic Linear Bottle Washing Machine Pick-Places

Typical / Example Specification

| Parameter | Value / Range | Notes |

|---|---|---|

| Bottle Size | Diameter: ~30-100 mm; Height: ~50-200 mm (varies by model) | Flat / square shapes may need change parts or special pockets. |

| Throughput / Output | ~30-40 bottles per minute; up to ~10,000 bottles/hour | |

| Number of Pockets / Carriers | ~10-20 pockets across the indexing carrier | Holds bottles in inverted (“neck down”) position during wash. |

| Wash Zones / Cycles | Multiple internal wash nozzles + external wash + air blow dry | Often 3-5 internal washes + 1 external + 1 air. |

| Water / Air Consumption | Water: 400-600 L/hr; Air: 5-6 Bar, ~20-30 CFM | Depends on size & speed. |

| Materials of Construction |

• SS316/316L (contact parts) • SS304 (frame/covers) • Springs, seals compatible with washing media • Acrylic / transparent covers for observation |

|

| Drive, Conveyor & Indexing Mechanism |

• Carrier pockets on indexing motion • Wire mesh / SS belt with oscillating guide rails • Automated pick & place with inverted wash |

Exit bottles upright after wash. |

| Power / Motor Requirements | Main drive motor 1-5 HP; pump motors 1-2 HP each; heater elements if hot water; 3-phase supply | |

| Utility Requirements |

• Electrical: 3-phase, 415V • Compressed air: 5-6 bar • Water: clean / filtered / DM water • Drainage & overflow protection |

|

| Frame / Overall Dimensions | Varies by model; Height ~1.4-1.7 m; Length several meters | Footprint depends on pockets & wash stations. |

| Special Features / Controls |

• No container - no washing interlock • No wash - no water supply mode • Variable speed (VFD) • Quick changeover parts • Separate wash circuits • CIP provision • GMP compliance |

What to Decide / Provide for Final Specification

- Bottle dimensions: diameter (neck & body), height, shape (round/square/flat).

- Desired throughput: bottles per minute / hour.

- Washing media: water, hot water, steam, chemical rinses, air drying, etc.

- Hygiene / compliance: pharma-grade, food-grade, etc.

- Utilities: power voltage, compressed air, water type, space & footprint constraints.

- Changeover frequency: how often bottles sizes change & speed of part swaps.

- Budget constraints & sourcing (local vs imported materials & features).

Semi-Automatic Rotary Bottle Washing Machine

| Parameter | Typical Value / Range | Notes / Variants |

|---|---|---|

| Machine Principle & Mechanism | Rotary indexing / “Geneva” mechanism | Allows intermittent motion, gives dwell time for wash cycles. |

| Washing Zones / Wash Cycles | Usually 5 cycles: 4 internal + 1 external; some include air wash | Cycles may use hot water, DM/RO water, or air. Sequence customizable per SOP. |

| Bottle Types / Sizes | Round, Flat / Square bottles; Neck Ø 20-30 mm; Height ~50-270 mm; Diameter 30-100 mm | Change parts (holders, neck pockets, cups) required when switching bottle sizes/shapes. |

| Number of Bottle Holders / Pockets | Common: 64, 80, 96 holders; smaller models ~32 | More pockets = higher throughput but larger footprint. |

| Throughput / Output | ~30-40 bottles/min up to ~80-120 bottles/min | Hourly: ~2,600-9,000 bottles/hr (64-96 pockets). Depends on bottle size, shape, neck opening, and operator speed. |

| Water Consumption | ~200-230 L/hr per wash zone; outer wash ~200 L/hr | Recirculation tanks reduce fresh water usage. |

| Tanks | 2 SS tanks (SS 304/316 contact parts), ~50-75 L each | One for fresh/DM/purified water, other for recirculated water. |

| Power / Motor | Main motor ~0.5 HP; pumps ~1 HP each; heater ~3 kW; 3-phase 415V, 50 Hz | Scaled up for larger bottles / higher speed machines. |

| Heater | ~3 kW heater (for hot water wash cycles) | |

| Air / Compressed Air | ~5-6 bar; ~5 CFM | Required if air wash stage included. |

| Height / Ergonomics | Working/loading height ~800-1000 mm | Designed for manual loading/unloading. |

| Dimensions & Weight | Length/width ~1.5-2 m; height ~1.3-1.8 m; weight 400-800 kg | Varies by capacity and model. |

| Material of Construction | Frame/body: SS 304; Contact parts: SS 316; some MS (non-pharma) | |

| Controls & Features | Solenoid valves, spray nozzles, optional air wash, manual loading/unloading, PLC/HMI (optional), emergency stop | Change parts required for bottle size change. |

| Safety / GMP Compliance | GMP / cGMP standards, sanitary design, leakage prevention | Pharma / food-grade applications. |

Key Optional / Customisable Features

- Ability to handle flat / square bottles as well as round bottles

- Air wash / air jet stage for moisture removal / final rinse

- Multiple wash media: detergent, hot water, DM / purified water rinse

- Adjustable / modular change parts for neck size, bottle height

- PLC / touchscreen HMI for better control & monitoring

- Utility hooks: separate electrical panel, splash guards, detachable tanks

- Water recirculation, filters, treatment to reduce consumption

- Pre-filtration (DM / RO / WFI water), fine filters

Fully Automatic Air-jet Bottle Washing Machine

| Parameter | Typical Values / Range | Comments |

|---|---|---|

| Output / Speed | ~ 40 – 150 Bottles/min (linear models); up to ~ 300 BPM in high-speed lines | |

| Bottle / Container Diameter | Up to ~ 60 – 100 mm | Can be larger with special change parts |

| Bottle Height | ~ 45 – 270 mm | Adjustable in some machines |

| Neck Diameter / Neck Holder | Change parts for different neck sizes | “Mouth holder” changes |

| Cleaning Cycle | Air jet blowing (positive pressure), vacuum cleaning, sometimes water wash | Typically 4–6 air washes or more |

| Air Pressure & Consumption | 4 – 6 kg/cm², ~ 400 L/min or ~ 20 – 30 CFM | Depends on bottle size & nozzles |

| Power / Electrical Requirements | 3-phase motors, ~ 0.5 HP to 20 HP | Voltage: 415 V, 50 Hz (India) |

| Materials of Construction (MOC) | SS 304 / SS 316L (contact parts); SS 304 (frame & covers) | |

| Machine Dimensions & Working Height | Length ~ 2 – 3 m (linear unit), height adjustable 850 – 950 mm | Depends on capacity |

| Utilities Required |

• Clean / filtered compressed air • Vacuum pump • 3-phase electrical supply • Water supply (if water wash feature) |

|

| Special Features / Controls |

• No bottle – no cleaning interlock • Overload clutch to prevent jams • Variable speed via inverter drives • Changeover parts for different bottle sizes • Dust collector / exhaust fan in chamber |

|