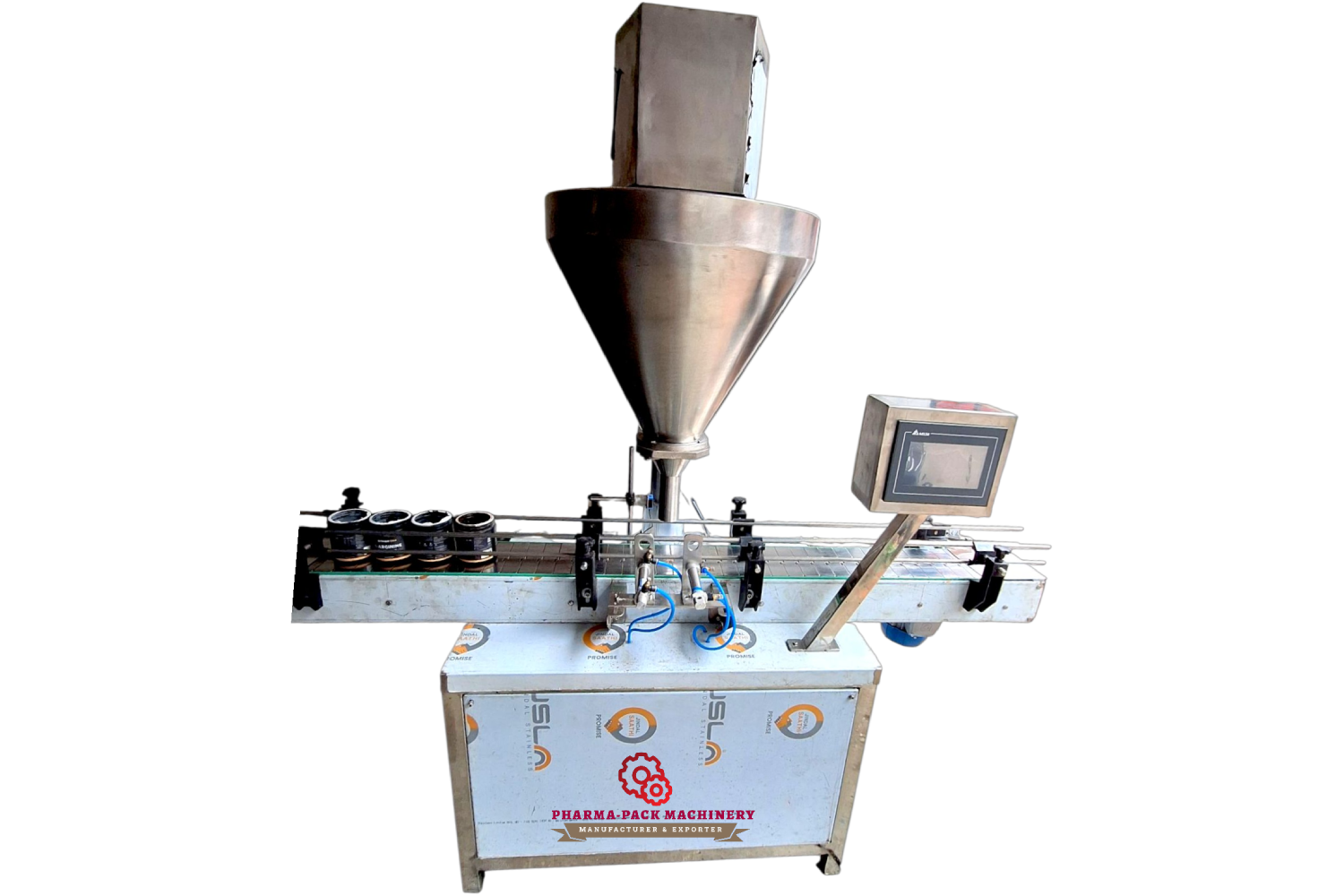

Automatic Auger Base Powder Bottle Filling Machine

| Typical Specification - Automatic Servo Auger, 1 Head Powder Filling Machine | ||

|---|---|---|

| Parameter | Typical Value / Range | Notes / Variants |

| Number of Filling Heads | 1 | Single head design; optional 2+ heads available |

| Filling Range (weight) | ~ 5 g to 500 g (up to 1 kg with change parts) | Depends on powder properties & auger size |

| Filling Speed | ~ 30-40 bottles per minute | For small fills (5-60 g) & free-flowing powders; slower for sticky powders |

| Accuracy / Tolerance | ± 2-3% (better for heavier fills) | Depends on powder flow, humidity, container neck, etc. |

| Container / Bottle Size | Diameter: ~25-85 mm; Height: up to 100-260 mm | Supports round/square, plastic/glass bottles; uses change parts |

| Machine Material of Construction | Frame: SS304; Contact parts: SS316 / SS316L | Ensures hygiene and corrosion resistance |

| Drive System | Servo motor (auger); VFD for conveyor | Timers or PLC may control auger speed/time |

| Electrical Power Supply | 3 Phase + Neutral + Earth; 220/380/415 V, 50/60 Hz | Depends on model & region |

| Air / Pneumatic Requirements | Clean, filtered, oil-free air; ~2-6 bar | Used for sensors, holders, actuators, safety interlocks |

| Hopper Capacity & Agitator | Typically 40-50 L with agitator | Prevents powder bridging, ensures consistent feeding |

| Conveyor / Bottle Handling | Adjustable height: ~850-910 mm | Includes holders, sensors, turntables; no-container-no-fill system |

| Machine Dimensions & Weight | L: ~1500-2000 mm, W: ~700-1100 mm, H: ~1650-2200 mm; Weight: ~300-600 kg | Heavier with dust enclosures, guards, etc. |

Optional Features / Extras

- Dust extractor / enclosure / acrylic guard

- Powder level sensors in hopper

- PLC + HMI touchscreen controls / recipe storage

- Safety guards and interlocks

- Change parts (different augers / funnels) for varied fill ranges

- “No bottle, no fill” feature

- Adjustable speed controls

- CIP (Clean-in-Place) or easy cleaning design

- Environment controls (humidity) - especially for pharma/food/cosmetic industries

Automatic Servo Auger Base 2-Head Powder Bottle Filling Machine

Typical Use / Function

- Designed to fill powders or micro granules into bottles or jars (food, pharmaceutical, chemical, cosmetic, etc.).

- Dual heads increase throughput (fills two bottles/jars in parallel or sequentially).

- Uses auger/screw metering (volumetric), often with servo-driven screw(s) for precision.

- “No Bottle, No Fill” safety and waste control system.

- Often built to meet GMP / cGMP norms: contact parts SS316, external frame SS304, easy to clean and hygienic.

Key Technical Specifications

| Specification | Typical Value / Range |

|---|---|

| Number of Filling Heads | 2 (Double head) |

| Filling Volume / Fill Range | ~5 grams up to 500-1000 grams (sometimes up to 2000g with change parts) |

| Production Speed (BPM) | ~40-80 bottles per minute Higher for small fills (5-10g); lower for large fills |

| Accuracy / Tolerance | ±1.0% to ±3% Typical ±2%; depends on powder type and fill size |

| Hopper Capacity | ~15-50 liters per head (or total), depending on model |

| Machine Dimensions (LXWXH) | ~2000-2500 mm X 900-1100 mm X 1500-2000 mm |

| Power / Electrical | 3-phase, ~400-440 V, 50 Hz Power: 1-3 kW depending on auger, servo, agitator, conveyors |

| Pneumatic / Air Requirements | Compressed air: ~3-6 kg/cm² For bottle holding, sensors, actuators |

| Other Utilities / Features |

• Conveyor system for infeed/outfeed • Servo motors / AC drives for auger screw • PLC + HMI with parameter setting & recipe storage • SS316 contact parts, SS304 frame • Optional: Dust extraction, safety guards, level sensors, change parts |

Practical Considerations / What Affects Performance

- Powder Properties: Flowability, bulk density, particle size, and moisture affect performance.

- Change Parts: Required for different fill weights/bottle sizes (augers, funnels, star wheels).

- Cleaning & Hygiene: Important for food/pharma use. SS316 contact parts, easy disassembly, minimal crevices preferred.

- Accuracy vs Speed: Higher speed can reduce accuracy, especially for small fills; multiple dosing can help.

- Utilities: Ensure stable power, compressed air, dust extraction, and appropriate ambient conditions.

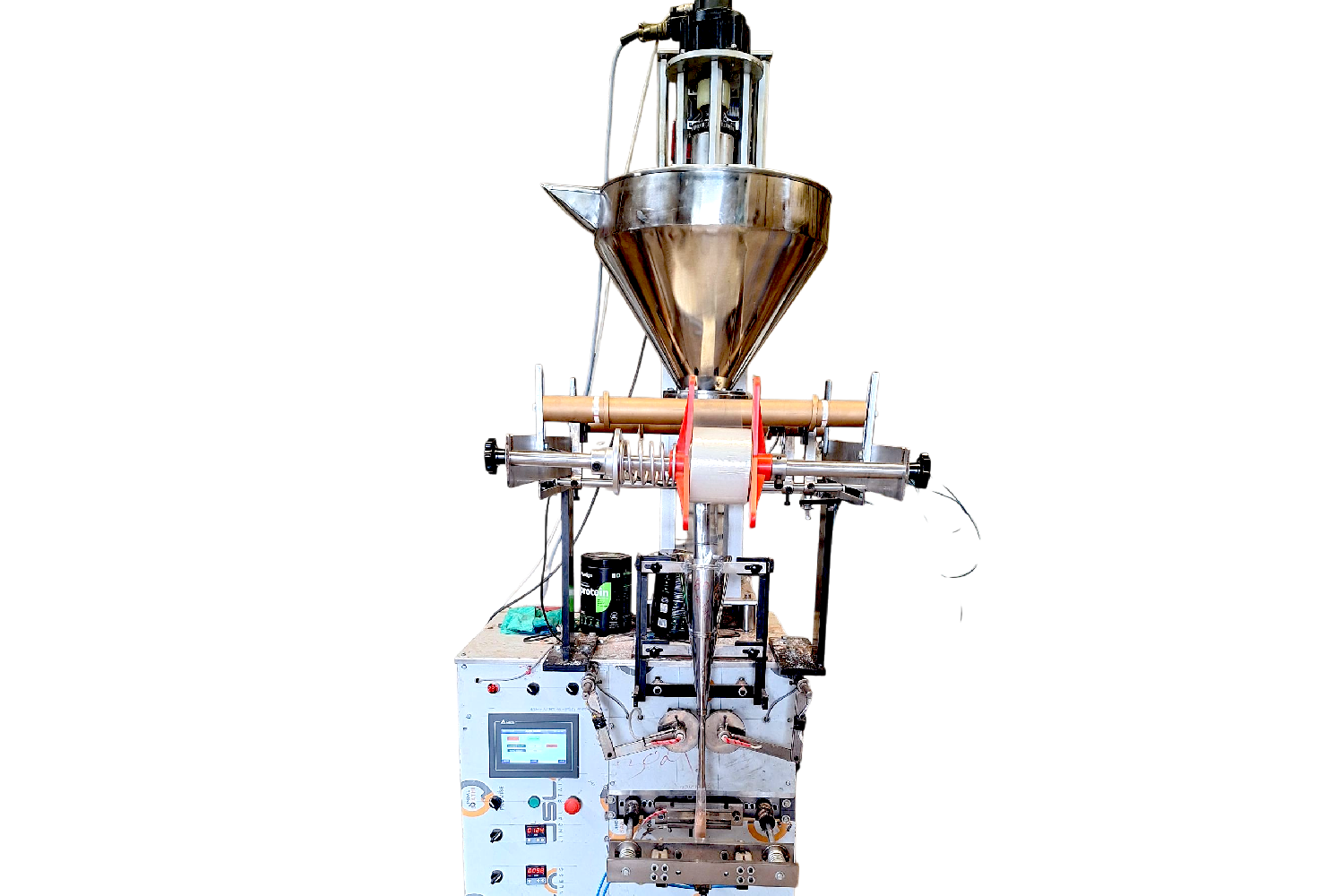

Automatic Pouch Filling-Sealing Machine (Auger Base - Powder FFS)

Product Features

- Online counting system

- Easy to operate & maintain

- Digital temperature controller

- Batch cutting system available

- Pouch length adjustable by programmer controller

- Nitrogen flushing system available (if required)

- Accurate sealing & cutting impression

- Low waste disposal

- Fully automatic compact and robust machine

Technical Specifications

| Specification | Details |

|---|---|

| Capacity | 10-100 gm, 100-250 gm, 100-500 gm (Different machine models) |

| Filling System | Volumetric Cup Filler Base / Auger Filler Base |

| Packing Material | Any heat sealable laminate film |

| Type of Sealing | Center Seal |

| Operating System | Horizontal Seal Pneumatic Base |

| Speed | 20 to 25 pouches/min (varies with product nature & fill weight) |

| Pouch Pulling | Pouch pulling by electronic motor |

| Power | ½ HP Motor, Single Phase |

| Photocell System | Available |

| Batch Coding System | Optional - as per your requirement |

Semi-Automatic Auger Base Powder Filling Machine

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Semi-Automatic Auger Filling Machine |

| Filling Principle | Auger Screw System (Volumetric/Weight-based) |

| Filling Range | 10g to 5kg (customizable) |

| Accuracy | ±1% (depends on powder and consistency) |

| Hopper Capacity | 25 - 50 Liters (customizable) |

| Filling Speed | 10 - 30 fills/min (depends on operator and size) |

| Control System | PLC or Digital Control Panel |

| Power Supply | 220V / 50Hz / Single Phase (customizable) |

| Power Consumption | 0.5 - 1.5 kW |

| Machine Material | SS304 / SS316 (contact parts) |

| Nozzle Types | Interchangeable for different container sizes |

| Operation Mode | Foot pedal or button start |

| Weighing System | Optional (load cell for high accuracy) |

| Container Types | Bottles, jars, pouches, cans |

| Application | Spices, protein powders, pharmaceuticals, flour, milk powder, chemicals, etc. |

| Dimensions (LXWXH) | Approx. 600 x 800 x 1600 mm (varies by model) |

| Weight | 100 - 200 kg (depending on model) |

| Air Consumption | Not always required (depends on optional features) |

| Optional Features | Dust collector, vibrator, nitrogen flushing, servo motor for auger |

Applications / Uses

- Food industry: Spices, baking powder, milk powder, protein powder

- Pharmaceutical: Ayurvedic and chemical powders

- Cosmetics: Talc, face powders

- Agriculture: Pesticide powders, feed supplements