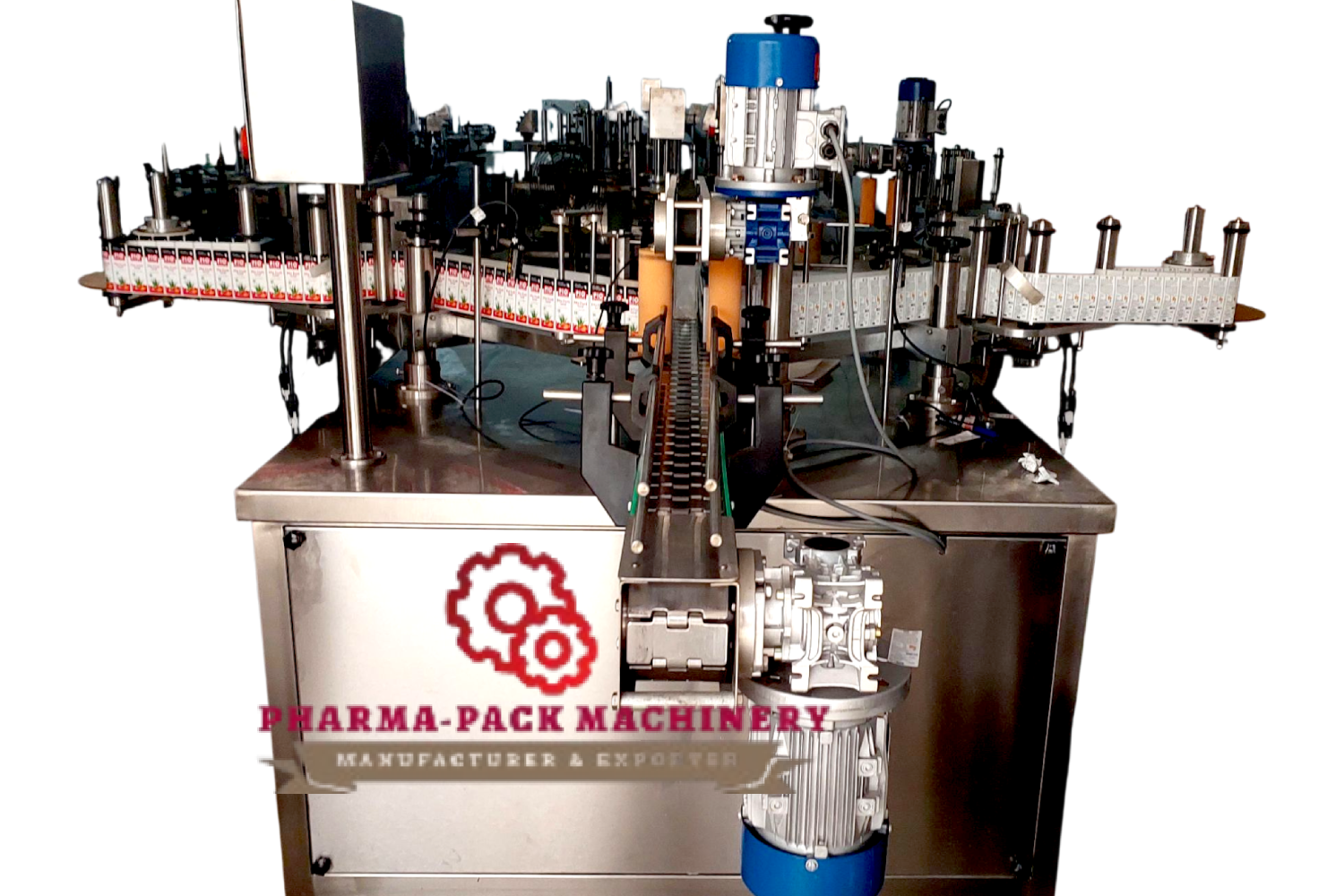

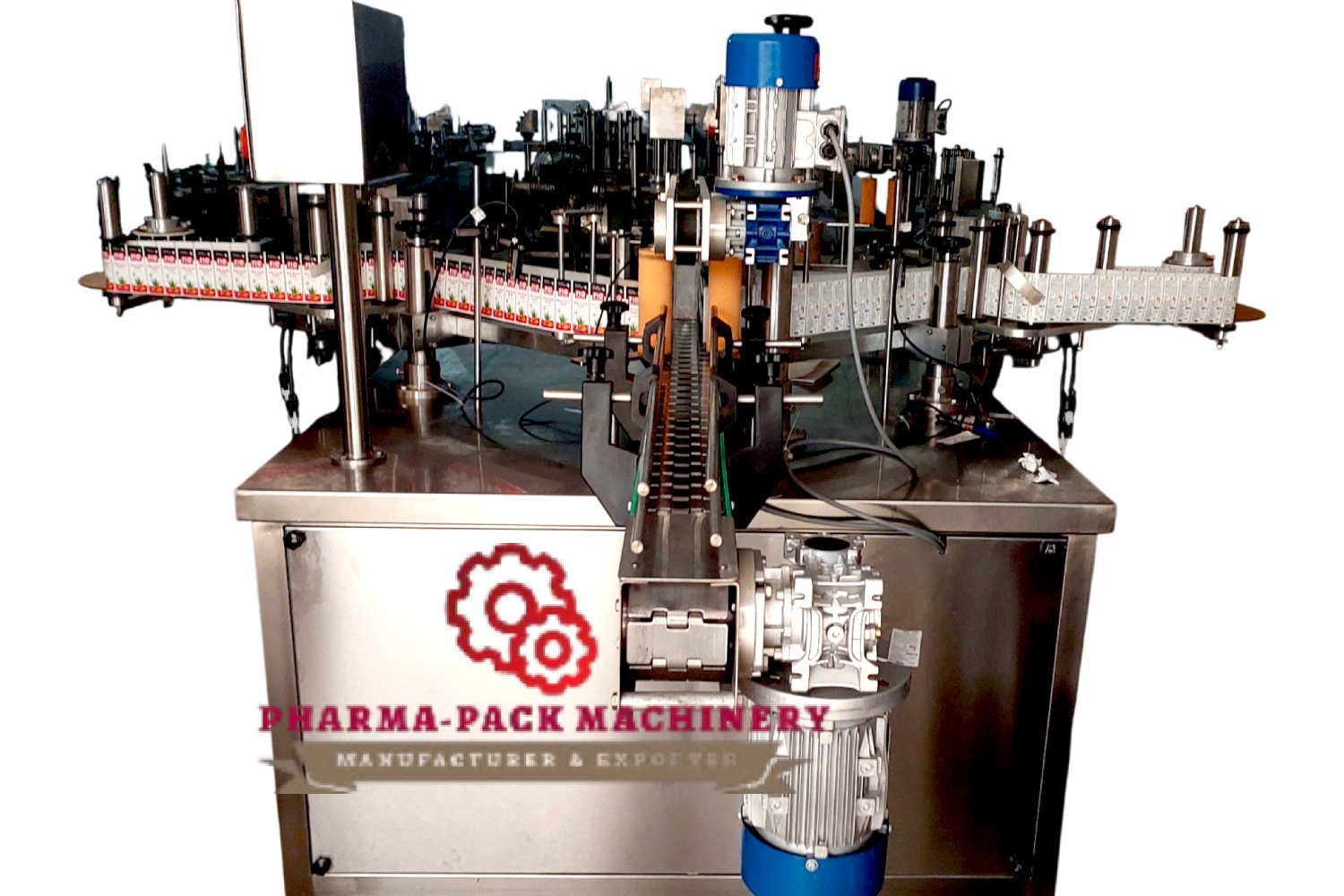

Automatic Double Side Sticker Labelling Machine

| Parameter | Typical Value / Range |

|---|---|

| Machine Type | Fully automatic, double side (front & back) self-adhesive sticker labeller |

| Speed (Output per minute) | ~60 - 300 containers/min (depends on container shape & label size) |

| Container / Bottle Types | Round, flat, oval, rectangular, square bottles / jars / containers |

| Label Material | Self-adhesive / pressure-sensitive labels; film or hologram labels depending on variant |

| Label Height | ~8 - 200 mm (depending on model) |

| Label Length | Minimum ~12 mm; upper limit depends on model |

| Gap Between Labels | ~3 mm minimum |

| Label Roll Diameter & Core | Max Ø ~300 - 400 mm; core ~75 - 76 mm |

| Container Size Range | Diameter/Width ~20 - 90 mm or greater (depending on model) |

| Material of Construction (MOC) | Stainless Steel 304, anodized aluminium, food/pharma grade |

| Power Supply | Single-phase AC 230V 50Hz (sometimes 3-phase); ~1 - 3 kW |

| Drive & Control | Servo/stepper motors, AC variable drives, PLC with HMI, sensors for detection |

| Accuracy | ±1 mm (±1-1.5 mm in some models) |

| Tolerance / Stop Precision | ±1 mm (or better) |

| Conveyor / Product Handling | In-feed & out-feed conveyors, spacing device/worm/pocket system, optional top stabilization belt |

| Dimensions & Weight | ~2.5 - 3.0 m (L) X 1.4 - 2.1 m (W) X 1.5 - 1.8 m (H); ~250 - 650 kg |

Key Features / Options

- Dual independent label dispensers (front & back) for different label sizes or types

- “No bottle, no label” feature to prevent mislabelling

- Label jam / missing label detection with stop & alarm

- Adjustable conveyor height & guides for different containers

- Top stabilization belts for oval/flat bottles

- Built-in counters, speed settings, PLC/HMI controls

- Optional batch/date/code printing (inkjet, etc.)

- Safety covers, guarding, touch screen colour display

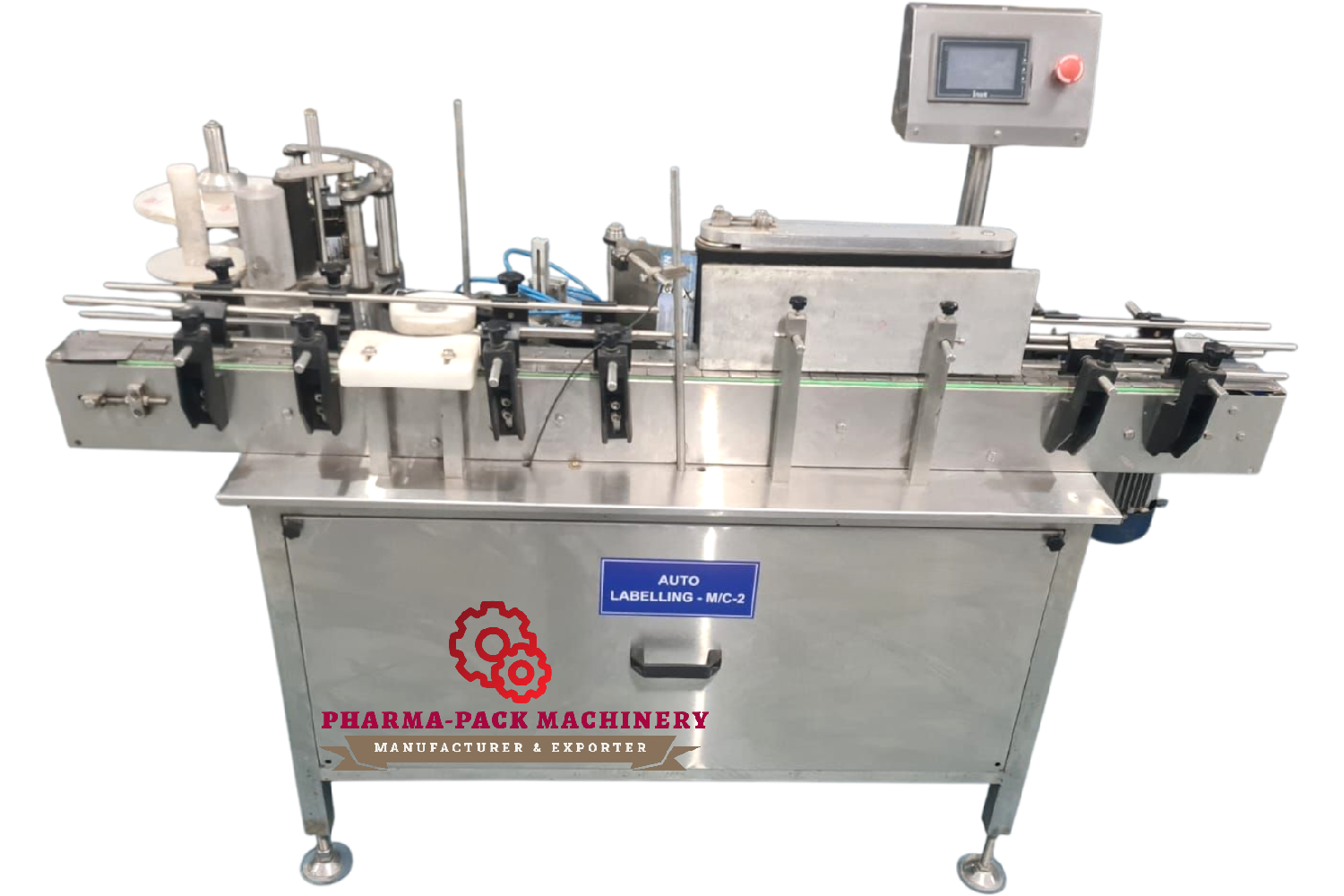

Automatic Round Bottle Sticker Labelling Machine

Typical Features & Components

- Automatic / PLC-controlled operation

- Self-adhesive sticker labels (paper / synthetic) in roll form

- Sensors:

- Bottle sensor (detects presence of bottle)

- Label gap or registration sensor

- Drive systems:

- Conveyor drive (variable speed, often VFD)

- Label dispensing motor (stepper / servo)

- Bottle separation / spacing device

- Wrap-around or partial wrap mechanism

- Pressing / smoothing belt or pad to fix label

- Touch screen / HMI for control (speed, count, etc.)

- Stainless steel frame and covers (hygienic, durable)

- “No bottle, no labelling” feature

- Optional coding / printing module (batch no., date)

| Parameter | Typical / Example Values |

|---|---|

| Speed (labels / bottles per minute) | 40 - 120 bottles/min (depends on label size, bottle shape & size) |

| Bottle diameter range | Φ25 mm up to Φ120-150 mm or more |

| Bottle height | ~25 mm up to ~200-300 mm (depends on model) |

| Label height & length | Height: 8-90 mm; Length: 12 mm up to several hundred mm |

| Label roll core & max roll diameter | Core: ~75-76 mm; Outer Ø: ~300-400 mm |

| Electrical supply / power | AC 220-230 V, single phase; ~1-3 kW. Some models 3-phase |

| Conveyor height | ~800-900 mm (adjustable) |

| Dimensions & weight | ~2000-2450 mm L X 900-1100 mm W X 1300-1550 mm H; ~200-400+ kg |

| Accuracy / positioning tolerance | ±0.5 - 1 mm under stable conditions |

Automatic Square Bottle Single Side Sticker Labelling Machine

Key Features & Benefits

| Feature | Purpose / Benefit |

|---|---|

| Single side sticker labelling | Applies label to one side of a square (or flat) bottle. |

| Pocket-type / feed worm alignment & top holding belt | Keeps bottles stable & straight for precise placement. |

| Label dispensing system with sensing | Detects product arrival & label gap; ensures correct alignment. |

| Variable speed drive (servo / VFD / frequency drive) | Allows adjusting speed as per bottle & label size. |

| “No bottle, no label” sensor | Prevents wastage; labels only when product is present. |

| Adjustable height & position | Applicator can be shifted up/down or sideways for different bottles. |

| Stainless steel construction (SS 304) | Ensures hygiene, easy cleaning, and durability. |

Typical Technical Specifications

| Parameter | Typical Range / Values |

|---|---|

| Speed (labels per minute) | 30 - 150 (some models up to 200+) |

| Label roll outer diameter | ~300 mm (up to 400 mm in some machines) |

| Core diameter of label roll | ~75-76 mm |

| Gap between labels | Min. ~3 mm (sometimes 5 mm depending on sensor) |

| Label height | Max ~80-160 mm (varies by machine) |

| Bottle size (width / height / panel) | ~20-120 mm width or more, depending on model |

| Conveyor height from floor | ~800-900 mm (± tolerance) |

| Electrical supply | 230 V AC, single phase, 50/60 Hz; some high-speed models need 3-phase |

| Power consumption | Typically 1-2 HP; higher for larger / faster machines |

| Accuracy of label placement | ±0.5 - 1 mm |

| Machine dimensions | L: ~1.5-2.5 m; W: ~0.6-1.6 m; H: ~1.2-1.8 m |

| Weight | ~200 - 500+ kg |

Example Specifications (From Actual Machines)

- Shivam Pharma Packtech SSLM 100: 30-40 BPM; label height 10-160 mm; roll dia up to 300 mm; bottle side 20-120 mm.

- Bhagwati SBSL 120RF: Up to 60-120 BPM; ±1 mm accuracy; label roll dia max 400 mm; 3-phase supply; SS frame.

- Boss Packaging SSVL FB: ~100 BPM; ±0.5-1 mm accuracy; roll dia 300 mm; SS 304; PLC/HMI control.