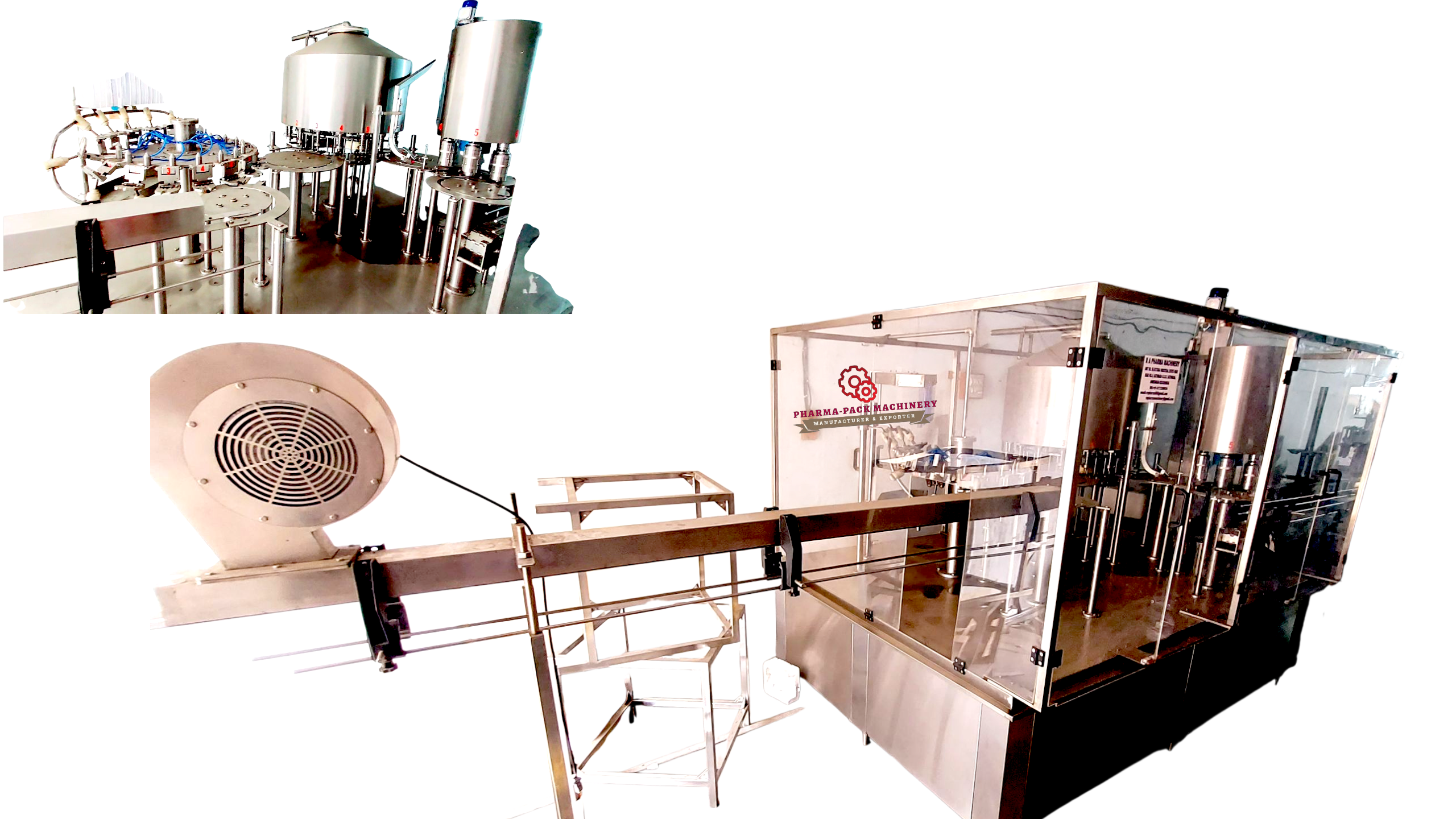

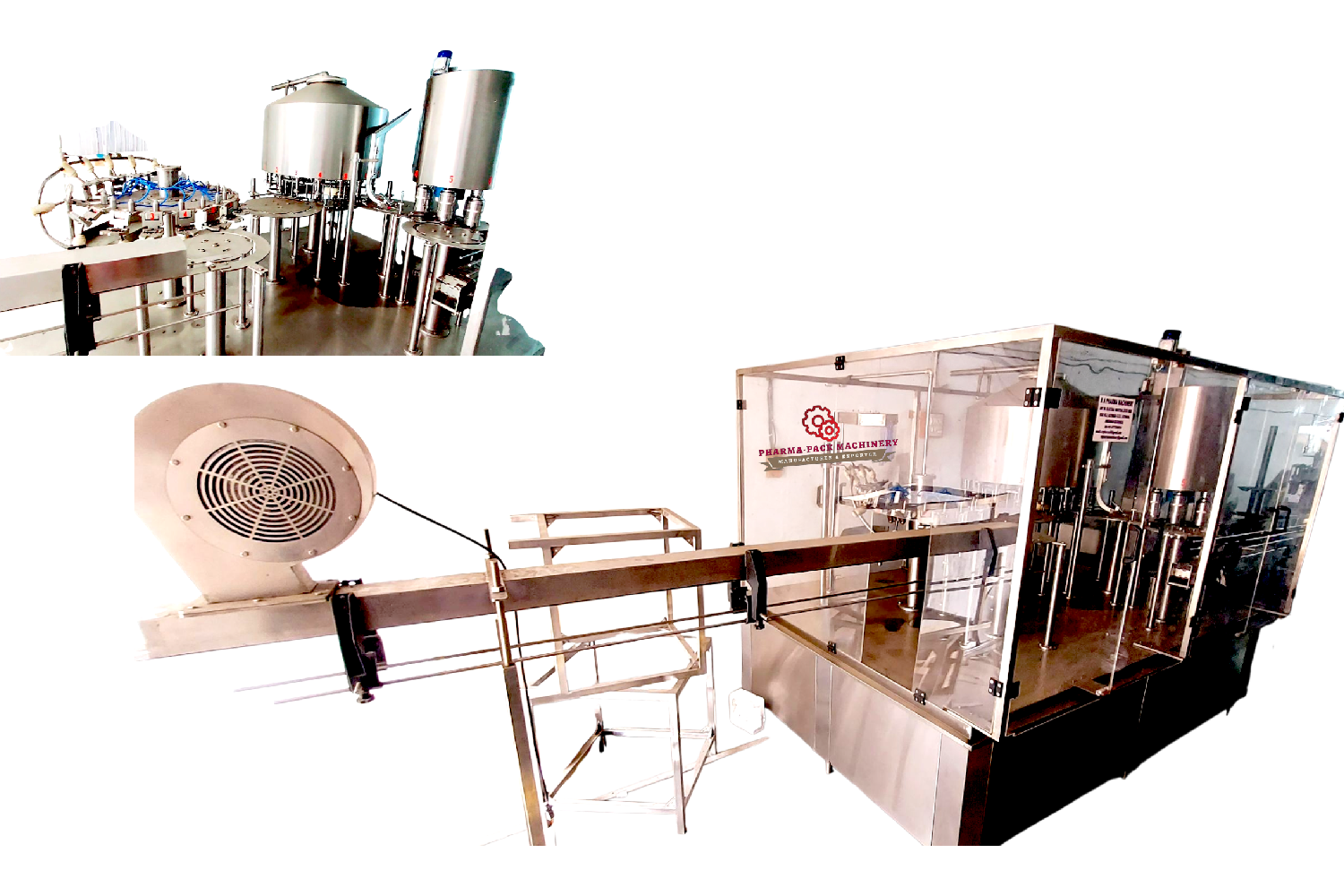

Water Bottle Rinsing Filling Capping Machine

Key Specification Parameters

| Parameter | Typical Values / Range |

|---|---|

| Capacity / Output | ~1,500 - 30,000 BPH (for 500 ml bottles) |

| Number of Heads (Rinse / Fill / Cap) | Example: 12-12-6, 24-24-8 (more heads = higher speed) |

| Bottle Size (Volume) | 200 ml - 2,000 ml (others possible with change parts) |

| Bottle Diameter & Height | Ø50 - Ø100 mm; Height 150 - 320 mm |

| Filling Accuracy / Level Control | ±1% (sometimes ±5 mm liquid level) |

| Filling Principle | Gravity filling (for water & low-viscosity liquids) |

| Rinsing Water Pressure | 0.1 - 0.3 MPa (≈1 - 3 bar) |

| Compressed Air / Gas Pressure | 0.6 - 0.8 MPa (6 - 8 bar) |

| Power Consumption | ~5 - 10 kW (higher for large machines) |

| Material of Construction | SS 304 / SS 316L (hygienic contact parts) |

| Electrical Supply | 3-Phase, 380-415 V, 50 Hz |

| Machine Dimensions | Example: 4500 X 2230 X 2700 mm (mid capacity) |

| Weight | ~1,500 - 10,000 kg (depends on capacity & heads) |

Essential Features & Options

- “No bottle — no rinse/fill/cap” interlocks for safety & waste prevention

- Pick-and-place capping with torque adjustable chucks

- Cap feeding: hopper + elevator + optional rinsing/UV sterilization

- PLC + touchscreen controls, sensors for detection & monitoring

- Hygienic stainless design, easy-clean nozzles, enclosed filling zone

- Change parts for different bottle sizes, necks & caps

- Auxiliaries: conveyors, inspection tables, safety interlocks & guard doors